TWK Cleaning Heads and Tools ranging from 2,000 psi to 23,200 psi can be used in all industries for tanks, vessels, reactors, containers or other internal equipment where surface fouling causes product quality problems; production delays as a result of long cleaning times between batches; and unsafe conditions for cleaning personnel.

Conventional cleaning of containers and tanks of all types is in many cases very time consuming and the results are not always satisfying.

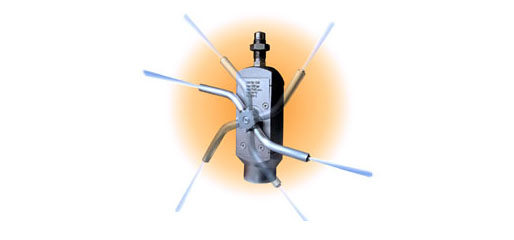

Automatic high pressure cleaning therefore asserts itself more and more: A high pressure plunger pump presses water through the nozzles of the TWK tank cleaning head with a pressure up to 1,600 bar / 23,200 psi.

The water jet cuts through the deposits and with its defined sequence of motion guarantees surface covering removal of these dirt deposits. In relation to the rules stipulated in the ATEX directive, the tank cleaning heads can be used in all ex-zones (except in mining). In fact, they can be used in explosion endangered atmospheres caused by gases, vapours, mists, and dust.

Cleaning the inside of tanks with high-pressure water is helpful to the environment. It does not require the use of chemicals, mechanical tools or boiling. The waste disposal of the accumulating cleaning water is limited to the separation of the cleaned off products. Compared with conventional methods, high-pressure cleaning is characterised by considerably shorter cleaning times and a better cleaning effect.

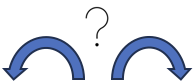

The correct positioning of the tank cleaning head is essential for optimal cleaning. The positioning devices and reel systems, which are individually adapted to the tank geometry, enable the performance of a tank-specific cleaning sequence. Lance systems serve the purpose of positioning the tank cleaning head TWK. These are characterised by the fixed positioning of the tank cleaning head in exact extension of the lance axis, both in vertical and slanted mounting position. The achievable stroke is 7 m plus.

The pressure-tight atmosphere when cleaning some chemicals in a tank cleaning container helps to enable “process integrated” cleaning. The cleaning process can be started immediately after draining off the product and does not require any preparations, i.e. cleaning takes place within the production atmosphere. Besides the improvement of product quality based on optimal cleaning results and low energy consumption due to the avoidance of thick deposits, production downtimes are reduced to a minimum.

Advantages of TWK Cleaning Heads and Tools:

- Effective: To date, the most thorough and fastest cleaning method. Reduces vessel “out of service” time which maximizes plant and equipment capacity. The best return on investment!

- Experience: With cleaning systems installed around the globe, our Uraca systems engineers have the experience to get the job done right the first time.

- 3D: Three dimensional cleaning effect cleans the entire vessel such that product quality and plant efficiency can be improved.

- Environmentally Friendly: Chemicals or solvents are eliminated as cleaning agents. The TWK units utilize water, which eliminates the need to dispose of environmentally hazardous substances.

- Flexible: Clean on demand. No more lost production time waiting for a cleaning.

- Control: Manual, semi- or fully-automated systems reduce personnel costs. As much control or as little as required to get the job done.

- Reduces Emmissions: Hermetically and/or pressure tight systems are available. Reduces the need to purge or flush vessels. Avoids the escape of hazardous discharges into the work area.

- Fast: Extremely efficient nozzles improve cleaning time, reduce water usage and electrical power consumption. Cleaning is measured in minutes not hours or days!

- Service: Fast service eliminates down time. Chemac Inc. is ready to service your URACA tools and systems 24 hours a day.

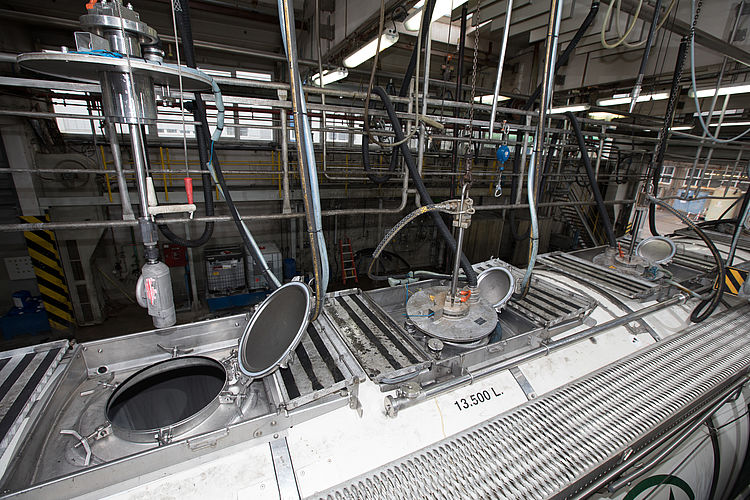

Regardless of how difficult the cleaning task may be, high-pressure water can clean surfaces easily. The chart above depicts typical representative pressures required to remove various materials.

Use of tank cleaning heads

High-pressure pumps from URACA generate the cleaning jet required for the hydrodynamic cleaning process. High-pressure water flows via a pipe or hose to the tank cleaning head positioned inside the container to be cleaned. It works either freely on a hose from above or via a high-pressure pipe vertically or horizontally in the container. The partially or fully automatic positioning by means of a special device is possible.

The degree of soiling determines the design of the tank cleaning head and the cleaning parameters such as operating pressure, flow rate, rotor speed and cleaning time.

How a tank cleaning head works

The tank cleaning head works on the basis of the hydrodynamic principle. The repulsion power of the water as it exits the nozzles drives the cleaning head. Together with the lever arm on the rotor, this generates a torque that causes the shaft to rotate. An external drive is not necessary. The internal gearbox transmits the rotary motion to the built-in eddy current brake and the connection shaft of the tank cleaning head. In addition, the head rotates about its longitudinal axis and rotates in two levels.

Tools & Accessories

All cleaning tools and Equipment from One Source

- Lances

- Motors (electric/diesel)

- Positioning Devices

- Pumps (up to 60,000.00psi

- Valves (foot, unloading, safety)

A high pressure cleaning system is safe, increases product quality and production, and offers a fast return on investment. Contact Chemac to find out more about how water can improve your plants productions and product quality.

If it has to be cleaned in the shortest time possible, it has to be a Uraca tool! Detailed information on all sizes and models available on request.