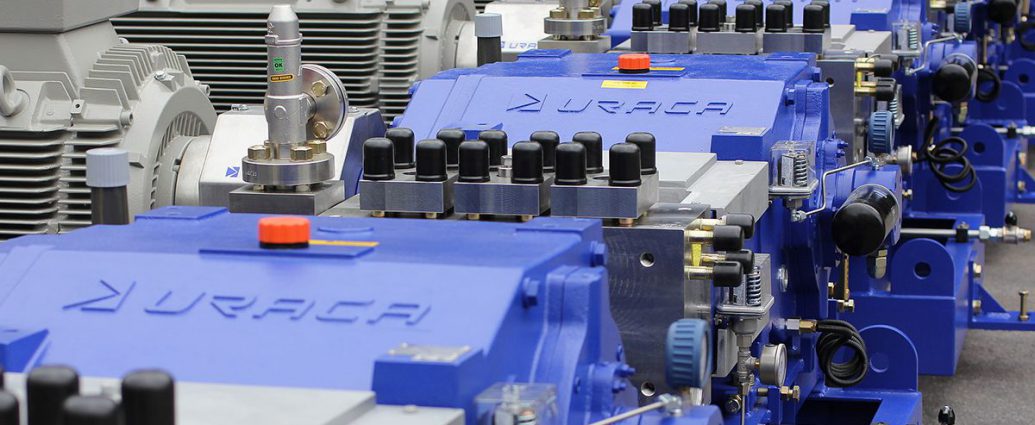

Chemac Inc. has been proudly offering URACA Multi-Plunger Pumps for High Pressure Water Blasting/Cleaning and Process Applications since 1966.

For High Pressure Water-Blasting and -Cleaning

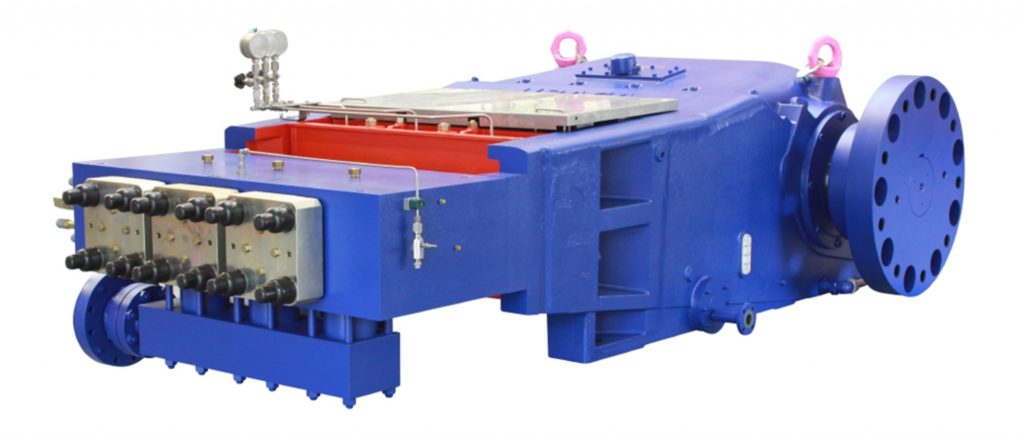

Our line of multi-plunger pumps is primarily for the high pressure water-blasting and water-cleaning industry, offering easy maintenance and excellent service life. The high-quality standards of the factory are evident in the quality design of the pump.

Benefits of the Uraca Pump Line

- Low maintenance

- Rugged design

- Long life for continuous or intermittent duty

- Flexibility — custom designs available

- Complete line of pumps

- Ease of use

- Easy to maintain

Applications

- Sewer cleaning

- Concrete demolition

- High pressure cleaning

- Descaling and deburring

- Cleaning systems

Performance

- Liquid ends up to 1,450 USGPM

- Pressures up to 40,000 psi

- Power frames up to 1,900 hp

- Medium: water

Options

- Skid Mounted

- Trailer Mounted

- Diesel

- Electric

- Bare or complete units

- Unloading valves

- Filters

- Pulsation dampers

- Cleaning tools

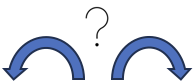

Hydraulic Performance Chart (Standard Units)

The chart below depicts performance of pumps and drivers, based upon discharge pressure and capacity. Example: for 300 lpm (79.3 USGPM) and 225 bar (3,263 psi) select a KD 825 pump.

Typical Applications

URACA Multi-Plunger Pumps for Process Applications

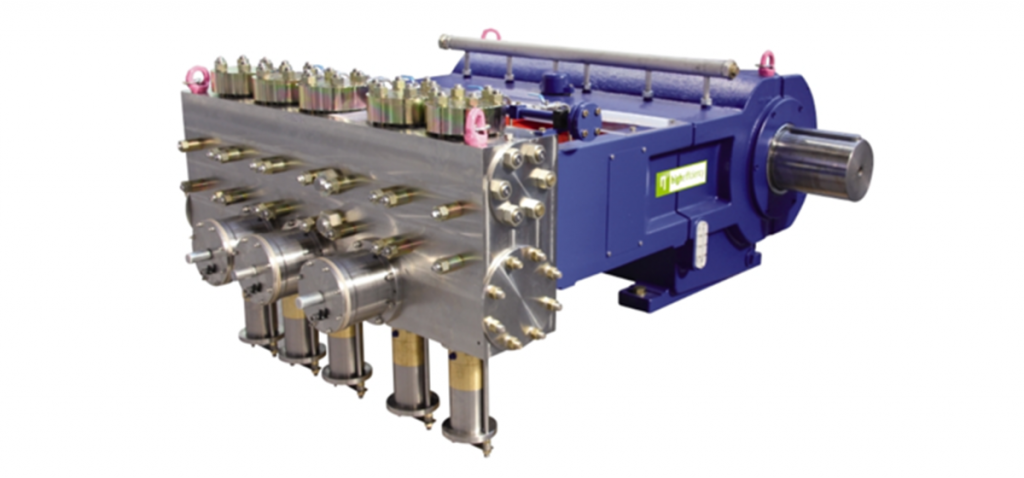

P-Series industrial high-pressure plunger pumps

Incorporating modern design for the performance range up to approx. 1,600 kW in round-the-clock, continuous duty.

The performance range of the URACA P-Series is subdivided into three groups:

- P3-80 (3 plungers)

- P5-80 (5 plungers)

- P7-80 (7 plungers)

The advantages of the P-Series pumps include compact design, good power-to-weight ratio, low operating costs, minimal pressure pulsation, and time-proven URACA quality. All power ends feature force-feed lubrication and oil cooling. Innovative monitoring systems ensure high operational reliability. The number of different components has been reduced to a minimum. Connection rod load and stroke, in addition to all power end internal components with the exception of the crankshaft, are identical on all models.

The liquid ends are also standardized accordingly (i.e. valve blocks and stuffing boxes), reducing the number of different parts. The process and industrial pumps P3-80, P5-80 and P7-80 have been designed for all conceivable pumping tasks in the range of high and ultra-high pressures:

- Low-viscosity to pasty

- Alkaline to acidic

- Neutral to toxic

- Clean to abrasive

KD Series Plunger Pumps

The URACA KD series plunger pumps are used for handling thin liquids to pasty substances with aggressive, neutral, abrasive, hot or toxic properties. The power ends are of standard design, whereas the liquid ends are custom built. The materials of the wetted part are selected according to the liquid, e.g. carbon steels, chromium steels, chrome nickel steels, duplex stainless steels, aluminum bronze, or if necessary Hastelloy, tantalum, titanium or inconel alloys.

The main features of the KD series pumps are forced power end lubrication and the exact alignment of the stuffing boxes within the power end, allowing for easy maintenance. Low specific loads on all moving parts prolong service life.

Contact us for info and specifications on other KD-Series pumps.

Benefits of our pump line:

- Safety

- Quality

- Long service life

- Excellent service

- Reliable and durable

- Triplex, quinteplex and septoplex pumps

- Accessories (valves, resonators, etc.)

Chemac can offer process plunger pumps for:

- Ammonia and Carbamate Service

- Slurries

- Detergents and soaps

- Oil, lubricants and pasty substances

- Acids and other caustic liquids

- C02 and other supercritical gases

- Forge Press, lubrication and descale pumps for steel manufacturing

- Off shore pumping units

- Oil field pumps

- Deburring pumps

To find the right Uraca pump for your application, simply fill our our pump selection data sheet and email it to chemac@chemacinc.com.

PDF Data Sheets: Uraca Multi-Plunger Pumps

- Pump Units

- KD 626V Horizontal Reciprocating Triplex Plunger Pump

- KD 629 High Pressure Reciprocating Triplex Plunger Pump

- KD 708 High Pressure Reciprocating Triplex Plunger Pump

- KD 716 High Pressure Reciprocating Triplex Plunger Pump

- KD 718 High Pressure Plunger Pump

- KD 719 High Pressure Reciprocating Plunger Pump

- KD 724 High Pressure Reciprocating Triplex Plunger Pump

- KD 725 High Pressure Reciprocating Triplex Plunger Pump

- KD 800 Series Pumps

- P-Series High Pressure Plunger Pumps

- Triplex Design

- Quadruplex Design

- Quintuplex Design

- UD 200 Pressure Transducer