New Bern, NC 04/11/2024

Lurking beneath the surface could be trouble. Calm water can be inviting and calming, but the trained eye must look for issues even when everything is looking good. A pump system could also be running fine, but if the operators are trained properly, they can identify issues that may show signs of trouble before they become an issue.

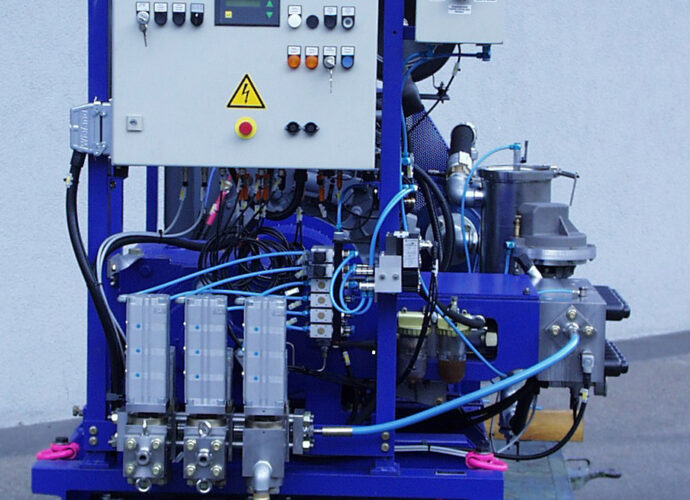

Even if a pump system is running at pressure and operational, there are possible issues to look for if the following occurs:

- Suction or discharge pipe shaking or lose bolts on either. This could indicate improper piping and or cavitation.

- Pump starts to knock, this can lead to valve failure and may also be related to cavitation.

- Clicking noise emanates from the pump. This could be due to sticking valves and may indicate they need replacing or are worn.

- Slow pressure loss – maybe to wearing nozzles/orifices on discharge side. Leaks.

- Hammering and pressure spikes – pump is being starved of medium. Booster pump or suctions lines may need inspection.

There are a several items which can suddenly manifest themselves via a smaller issue. It’s the small issues, when left alone or ignored can result in more costly repairs down the road. Is your team able to identify issues with your pump systems? If not, we recommend courses offered by the Hydraulic Institute or attending a Chemac Inc seminar.

Before repairs get more costly, it is important to have skills at site to identify a small problem lurking under the surface before it becomes a big problem. If interested, Chemac, Inc also offers site specific training at customer sites.