New Bern, NC 02/9/2023

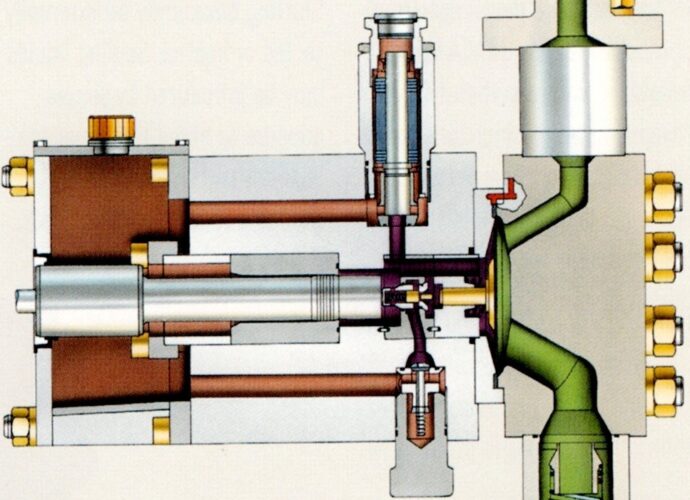

For many years, hardened stainless valves, stacked vertically with discharge valves over the suction valves, have been the standard for URACA pumps up to discharge pressures of 6000 psi, thanks to a good combination of resistance to corrosion and mechanical wear. However, these valves were unsuitable for industries where light oxidation can lead to discoloration of the end product. Instead, bronze valve seats are selected, which avoids this issue while still providing excellent wear life.

For many years, hardened stainless valves, stacked vertically with discharge valves over the suction valves, have been the standard for URACA pumps up to discharge pressures of 6000 psi, thanks to a good combination of resistance to corrosion and mechanical wear. However, these valves were unsuitable for industries where light oxidation can lead to discoloration of the end product. Instead, bronze valve seats are selected, which avoids this issue while still providing excellent wear life.

While the main wear point for both valve types is at the angled seating surface between the valve seat and cone, which can be resurfaced to extend the valve’s service life, the bronze valve seats will eventually become worn to the point they no longer accurately locate the valve seat, necessitating complete replacement after several years’ operation. To achieve even longer service life, Chemac is now offering valves with Duplex stainless seats as the new standard for certain applications. Duplex stainless offers superior corrosion resistance to 316 stainless steel, eliminating any risk of discoloration, while also offering superior resistance to mechanical wear. While re-cutting of the valve seats periodically is still necessary, with proper maintenance these valves can last for a decade or more.

While bronze seats will continue to be available for the foreseeable future, we strongly recommend taking advantage of the latest improvements when replacing valves; the stainless valves are a direct replacement with no additional replacement parts required. And valves are just one area in which Chemac can offer improved components for existing pumps; in many applications improved packing materials and plunger coatings can also offer better wear life with minimal changes to the existing pump. If your URACA pump has been in service for a while and is in need of new parts, Chemac will make sure you are up to date with all the latest advances in materials.

Customers are already accustomed to long run times with Uraca pumps… by upgrading valve material, the potential risk of product discoloration is eliminated and run times are greatly improved. Even for customers not impacted by discoloration, the increase run times may warrant the upgrade. Unsure if your pump needs upgrades? Contact Chemac, Inc for more information.