Bad Urach Germany: September 30, 2023

Typical applications of spray drying can be found in the chemical, pharmaceutical and food industries. As the process dries media in a few seconds, and in some cases, fractions of seconds, it works very gently. Especially for sensitive substances such as vitamins, hormones or proteins and essential oils, spray drying is ideal. The dried powder has a high solubility and good handling properties.

Sample applications include production of:

- milk powder

- powdered coffee

- powder glue

- hormones, proteins, vitamins

- detergent powder

- fertilizer

The Process

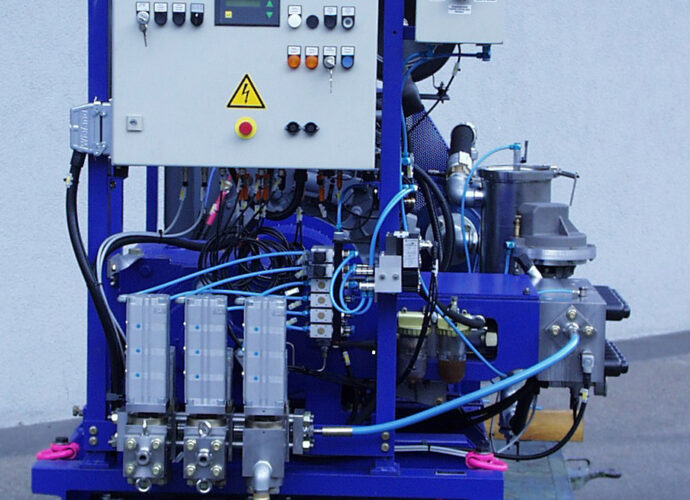

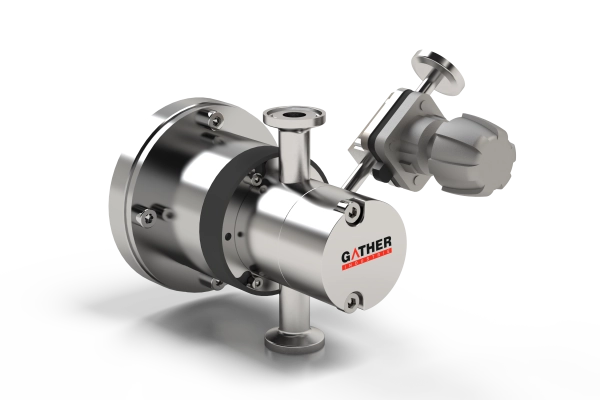

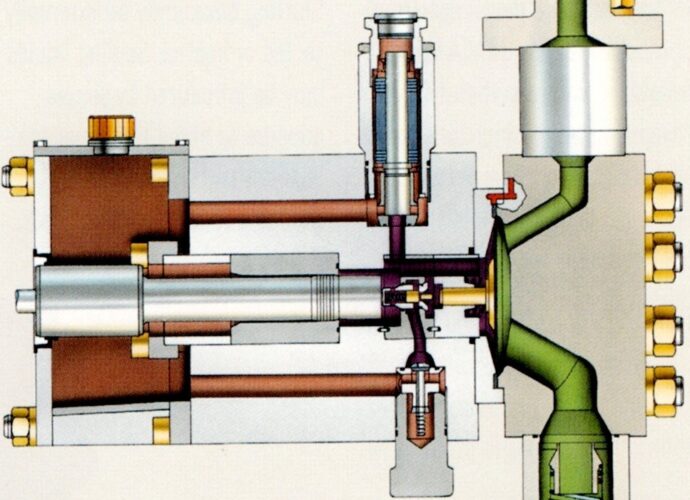

In the spray-drying process, nozzles atomize the solutions, emulsions or suspensions to be dried into fine droplets. In the concurrent or countercurrent principle, the drying then takes place with tempered air or inert gas. A cyclone separator then separates the dry particles from the drying air. URACA pumps spray the medium by pressing it through a single-fluid nozzle at a pressure between 50 to 250 bar.

The nozzle is usually located in the upper part of the spray tower, but can also be placed in the bottom of the tower and works much like a fountain. The droplet size is dependent on the surface tension and viscosity of the medium, the diameter of the nozzle opening and the spray pressure. By varying the nozzles and the pump pressure, it’s possible to find flexible solutions.

The Requirements

A special challenge is the adaptation of the liquid end of the pump to the abrasive and very pasty conveying media. For these applications, low speed pump units are used to minimize wear and tear of valves and stuffing box internals. The exact setting of the required transfer capacity requires a flexible and stepless control of the pumps.