New Bern, NC: 09/30/2023

New Bern, NC: 09/30/2023

Say “Goodbye” to the danger of cleaning confined spaces. In the past, cleaning confined spaces was a dangerous job. A large vessel or reactor would require a manual entry permit for an operator with a high-pressure lance/tool to waterblast the internals clean. Another option was to use a caustic solution to clean the internals of enclosed spaces. Both options could take several days to complete, leaving the vessel out of service until released back to the production team. The cost of down time, without the cleaning labor included, was in the hundreds of thousands of dollars for each vessel.

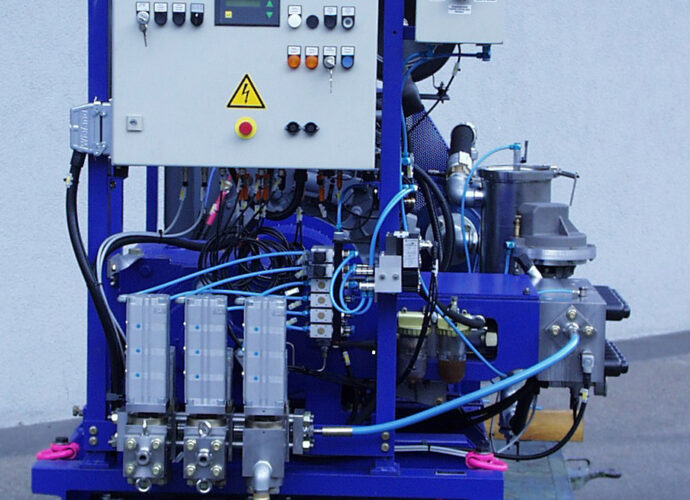

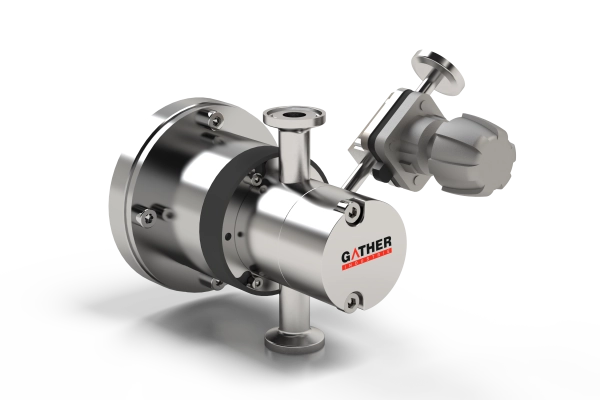

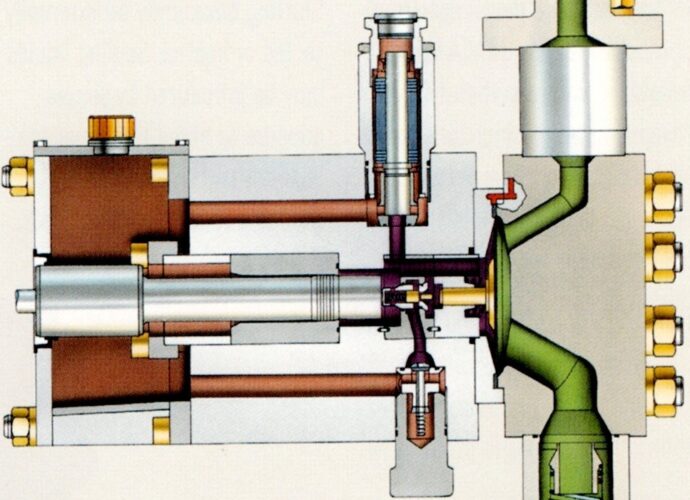

Today, almost all modern manufacturers use semi or fully automated systems to clean confined spaces. The benefits are so overwhelming, the cost of a system is quickly recovered in increased production and product quality. Furthermore, the reduced risk to operators saves in potential injury, fatigue and other issues related to manually working in confined spaces.

Cleaning with a modern 3D high pressure system uses only water to clean. Thus, the additional environmental benefits make this not only the best economical solution for cleaning, it also makes it the most environmentally friendly solution. Are you still using caustic or manual entry? Maybe the time has come to contact Chemac, Inc. and discuss installing a high-pressure cleaning system or systems to automate your cleaning.