Alvin, TX: September 27, 2023

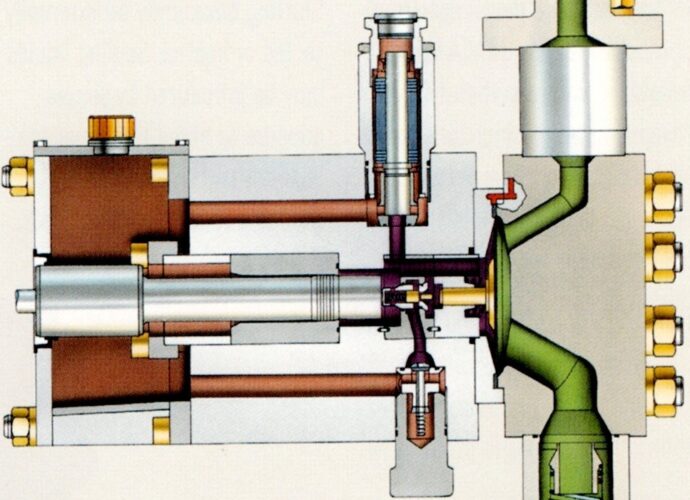

As strange as it sounds, a pump does not cause cavitation when working correctly. Cavitation is merely a result of an improper design, broken or worn pump, or a pump not set up per generally accepted procedures as commonly outlined by the Hydraulic Institute. How do you recognize you have a problem with cavitation? Common problems include:

- Vibration in the suction and discharge sides of the pump (often resulting in loosening of braces or breaking pipe supports)

- Hammering or knocking noises from pump and or valves

- High wear of pump parts indicating cavitation - excessive damage to valves and seats

- Damage caused by cavitation can shorten the life of a pump dramatically

- Pulsating pressure readings

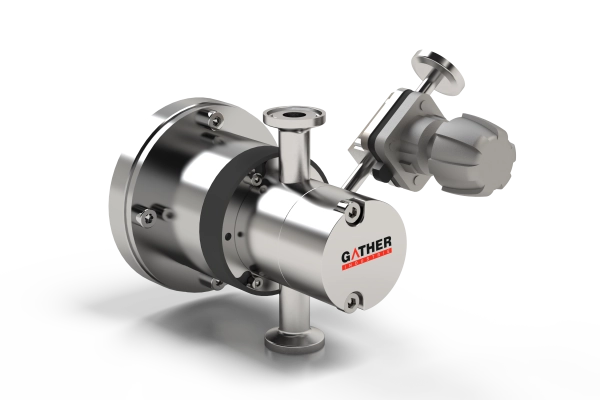

Parts can suffer damage from cavitation

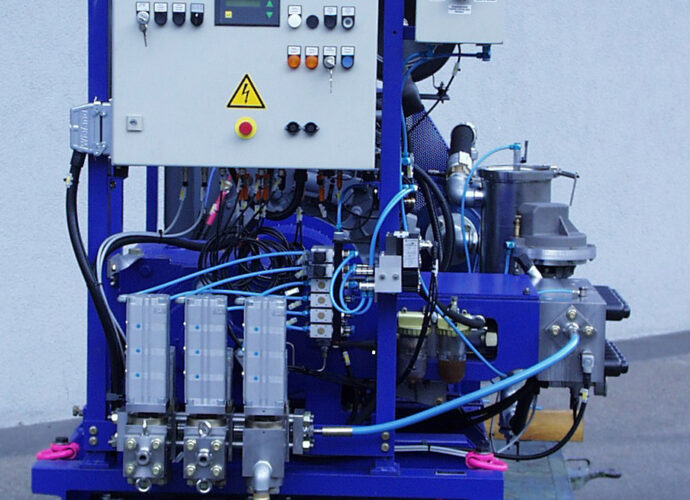

While plunger pumps all have “harmonics”, most pumps will run smoothly, if properly designed and installed. If your pump is suffering the negative effects of cavitation, then its time to act before the problems gets worse and more costly:

| Check Potential Causes | Solutions |

|---|---|

| Inlet line too small to pump suction side | Inlet line should be minimum 2x larger than pump input/suction line |

| Improper NPSH – too low or too high | Check NPSH R and ensure pump receives proper NPSH – install booster pump if too low |

| Suction/Discharge line with 90 degree bends before and after pump | All lines should be long sweeping bends |

| Discharge line has varying size lines | Maintain discharge size outlet of pump in discharge piping |

| Suction lines are too long or too small | Install Suction dampener suction side of pump or use flexible lines for 3 feet before suction and after discharge connection |

| Valves are not working/broken | Check valve function |

| Discharge line too long with 90 degree bends and multi-header discharge ports | Install discharge dampener |

| Filter incorrect or dirty | Check inlet filter size and clean |

| Incorrectly installed packing | Check packing and install correctly |

| Plunger scored/damaged, guide bushings and back rings warn | Replace all damaged scored parts |

| Excessive valve wear | Sign of cavitation. Repair and fix cavitation issues. |

| Medium contains air/bubbles | Check for leaks in suction line. Remove leaks from suction system. |

It is important to identify cavitation issues early as they can cause premature pump failure, excessive wear on parts/piping and cause more problems in the system. If the pump is running normally, cavitation is rarely from the pump itself, but the results of a piping/plumbing issue that damage the pump as a result of line cavitation. Thus, it is critical to look at the entire system when investigating the source of cavitation.

When designing a pump system, we recommend following the Hydraulic Institute Guidelines for laying out piping for any positive pressure system. The Hydraulic Institute makes excellent recommendations for designing a pump system to ensure cavitation from the system design doesn’t become a problem. If you have any questions, please feel free to contact us with problems you may be experiencing with pump systems issues.