New Bern, NC 1/31/2024

New Bern, NC 1/31/2024

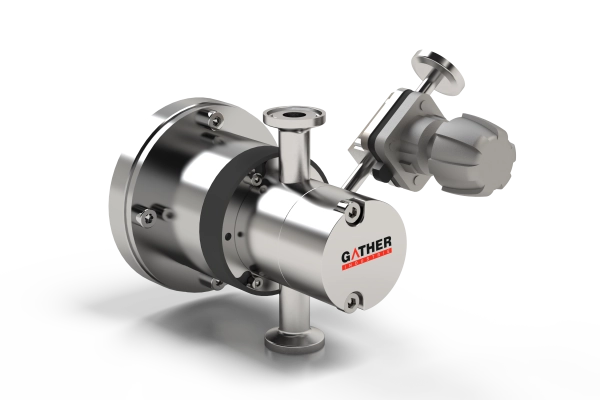

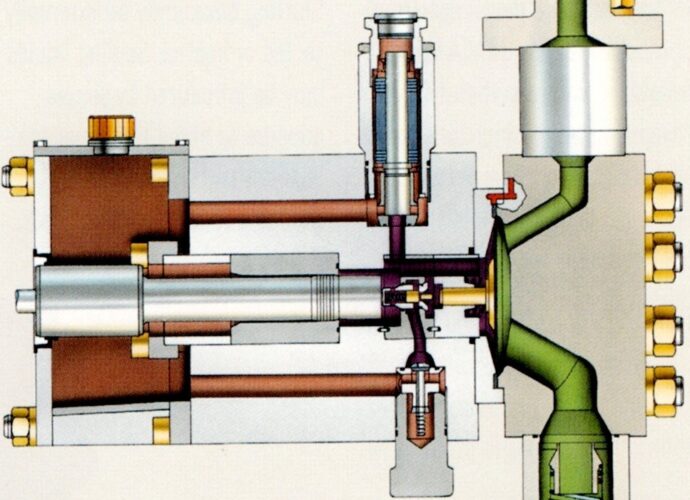

Most moving parts require lubrication and for internal gearing of a 3D tool, the proper lubrication is critical to the tool’s longevity and operational reliability.

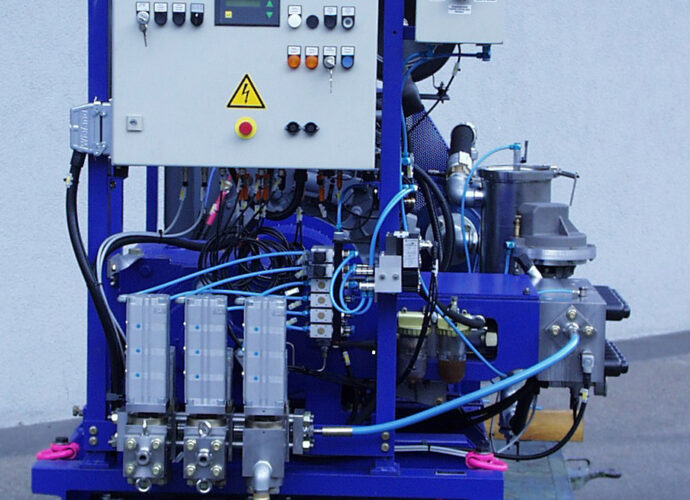

Packing the internals in grease is not necessary, only a light coating of approved grease is sufficient to ensure long run times. Each gear requires a coating of approved Uraca grease supplied by Chemac in tubes and boxes of up to 20 pcs. This excellent grease is factory-proven to maximize tool run times and keep gears operating as designed to provide long life of your plant investment.

Refer to the instruction books for each tool to perform the proper greasing method using only recommended grease will ensure the tools require less maintenance and parts.

For professional maintenance of all Uraca 3D tools, contact your Chemac representative for maintenance plans and/or support. Chemac stocks grease and supplies for your tools and supplies to get your tools back into service ASAP. If your plant prefers, please contact Robert Hardin at rhardin@chemacinc.com to receive an RMA # to ship your equipment to Chemac for professional servicing.