The only answer to cleaning of vessels and reactors where efficiency and safety are paramount.

Declare your firms independence from cleaning vessels and reactors with old outdated and dangerous methods! As a plant Engineer or Production Manager, you must wear many hats to keep your plant operational at peak performance. Safety, efficiency and plant optimization can be a constant challenge. So the question arises, why clean the old fashioned way with caustic or dangerous manual entry cleaning when there are clearer alternatives meeting your goals and are more environmentally friendly?

High pressure water is the only answer to cleaning of vessels and reactors where efficiency and safety are paramount. Let’s take, for example, a plant with a large 10,000 gallon vessel using caustic to clean out resins fouling the reactor. If the plant uses caustic, the caustic soak requires the vessel to be filled with caustic and the agitator must be turned on for approximately 12-18 hours for a good clean. After the caustic clean, the caustic is drained from the reactor and followed with an inspection. Only after this process can the vessel be handed back to production from the maintenance team. The caustic cleaning process can take upwards of 12-24 hours and requires enough caustic to fill the reactor or vessel. The contaminated caustic would then be required to disposed of. This process requires a lot of production time per cycle, storage of caustic at site (a potential hazard) and potential environmental issues with the large amounts of contaminated caustic @ 10,000 gallons per cycle.

Another option is cleaning with manual labor inside the vessel. This can be done with contractors using water jets and/or chisels to remove fouling. If the contractor uses water blast guns vs 3D tools, the contractor must get an entry permit to clean. Any method requiring manual entry into vessels is no longer recommended today for firms concerned about safety and efficiency. Since not all contractors are the same, the plant may have to schedule a full day to clean a single reactor.

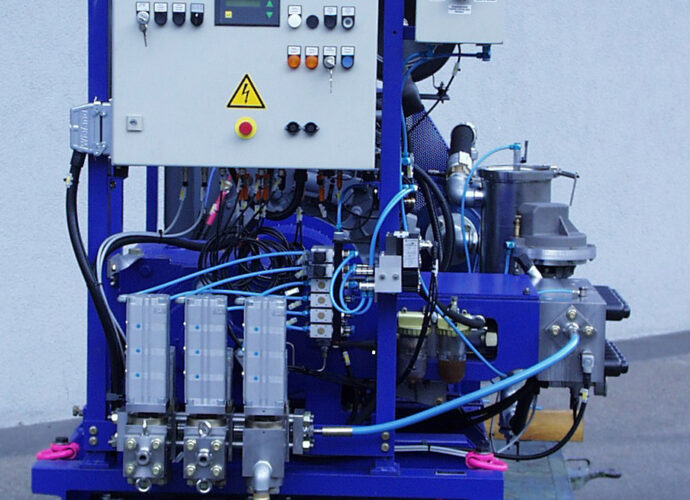

The best solution is using an automated or partially high pressure automated system, the benefits of this type of system includes:

- Environmentally Friendly

Using only water that can be treated and recycled with in plant systems. - More Production

Considering the cleaning time will be measured in minutes vs hours and or days, the same vessel(s) can produce more product than before. - Safety

An automated or semi-automated system doesn’t require manual entry and can be controlled from the safety of the control room. - Clean on demand

Makes changing product production quick & easy. - Durability

Our systems are designed to last many years with little maintenance. - Improved quality

By cleaning on demand or between batches, the end product can be improved. - Fast ROI

The return on investment for a high pressure cleaning systems averages 18 to 24 months depending on use and previous cleaning methods.

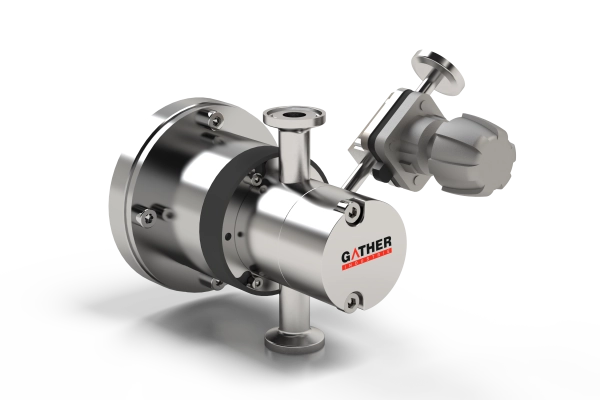

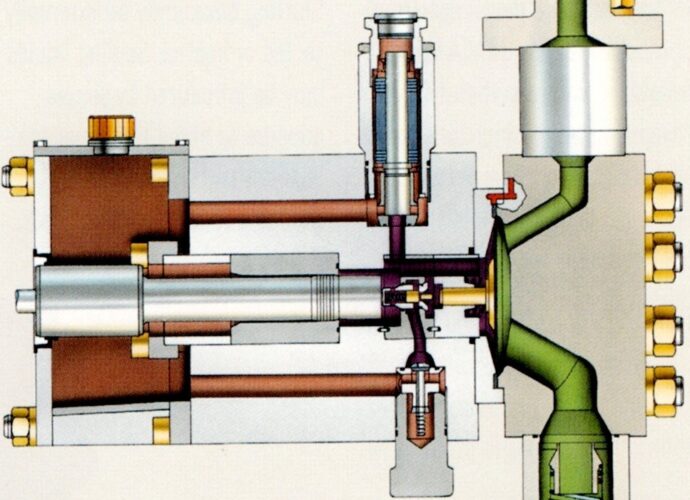

Although high pressure cleaning is the best “green” solution for cleaning, high pressure may not be needed for every cleaning application. High pressure cleaning is designed to clean by removing layers of deposits from vessel walls by peeling off these deposits using high pressure water jets. Compared to washing, or rinsing with pressure below 400psi, high pressure cleaning systems typically use pressures between 3,000 and 24,000psi.

The most common systems use pressures from 6,000-12,000 psi and up to 40 to 60usgpm. Each system is designed to maximize the cleaning impact and shorten vessel turn-around time.

Is your plant a candidate for high pressure cleaning?

Existing plants must take many factors into consideration when looking at a high pressure solution. These can be reviewed with a Chemac agent to determine if your vessels and reactors can benefit from high pressure cleaning. Common information we require for our review:

- A vessel drawing showing any internals and potential manways for cleaning access.

- Overhead dimensions for system entry options.

- Confirmation there is no existing lining in the vessel made of glass or rubber. Linings, if damaged, will be cleaned out of a vessel.

- List of goals for the cleaning process.

- Information on the existing plant cleaning process. How often is cleaning desired? Where is the fouling the worst? What process is used to clean presently? Does the plant know how much each cleaning cycle costs in plant down time?

- What is being cleaned? Not all applications require high pressure and each vessel and material systems designed to maximize efficiency and reliability.

- Estimate how much time is saved if cleaning can be done in minutes vs hours or days.

If cleaning in minutes vs hours/days is important to your operation, then high pressure cleaning system might be the best solution. In some cases, systems using high volume washing may consider using higher pressure for cleaning. Consider a washing system using 200-300 gpm at 80-120 psi. After cleaning only 10 minutes, water consumption is over 3,000 gallons. Alternatively, a higher pressure system may use upwards of 400 gallons for the same cleaning effect. These samples are purely for comparison purposes, actual results may vary depending on required flow/pressure, recycling systems and many other factors.

Interested to know if your plant can benefit from a high pressure cleaning system? Contact us online or call 1-800-217-8677.