The last thing a customer wants to experience is problems with a new piece of equipment. When the “equipment” is a high-pressure pump for a new process then any problems are critical to address before any damage results. Where do the problems come from? The pump is knocking so it must be the pump, right? Many are quick to blame equipment, but this may not be the case with many new installations.

As with any problems arising from a new system, an engineer needs to address any problems with a Sherlock approach. While a knocking pump may seem to have a simple culprit…it’s the pump, the actual problems may not be a pump problem. In one case, we had a customer buy a bare shaft pump and installed it on a mobile diesel system. The pump ran great during testing as part of a trailer mounted diesel unit, but when the unit was sold to a customer, the system would constantly shut down. The systems packager was quick to blame the pump. However, after a thorough investigation at the remote site, it turned out to be the company that built the diesel unit and not the pump OEM. The investigation determined the pump packager installed a valve in the feed tank incorrectly. Thus, instead of sending a signal to “pump”, the tank signaled it was “empty” and would shut down the pump within ten minutes of starting. Once the valve situation was fixed, the pump unit ran flawlessly.

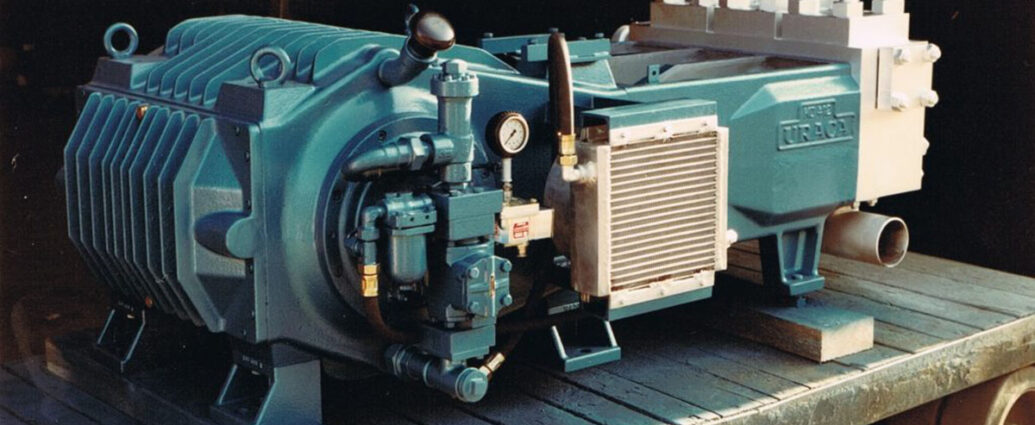

In another situation, an end user bought an engineered pump system. After the install, the pump was knocking and the buyer believed the valves were not operating properly. The site called for a Chemac specialist to investigate and it was quickly determined that the pump was pulling in air through the suction line resulting in cavitation. Once the entrapped air was resolved, the pump ran without any further issues.

In short, some pump issues may not even be related to the pump. There are numerous issues that can arise for new or updated systems, these can include, but are not limited to:

- Improperly designed suction tanks.

- Improperly designed suction and/or discharge piping (undersized, or too many turns) and/or wrong filters.

- Improperly designed pulsation dampeners.

- Insufficient NPSH (common with under sized booster pumps or no booster pumps installed).

- Designs that allow air/gas entering the pump.

- For multi-pump applications improperly designed suction distribution header/piping.

- Improper alignment between driver and pump.

- Insufficient brackets/supports on discharge piping.

These are just some issues that can result in initial startup problems of some systems. Thus, when designing a pumping system for an application, it is highly recommended to have Chemac review the piping specs on the suction and discharge side of the pump. Problems identified early in the design phase could save tens of thousands of dollars in repairs, or modifications, after startup. All too often the same issues seem to arise or where overlooked. The good news, there are many resources for the proper planning of pumping systems. One good resource is the Hydraulic Institute based in NJ or just checking with Chemac Inc during the planning phase. Either way, there are numerous resources to help you project become a success. Let us know how we may be of service.