The crankshaft is not typically a spare part that needs to be replaced. In fact, if properly maintained, the crankshaft can have an unlimited equipment life. However, if not properly used/maintained, it can result in premature failure. A failure could result in more serious damage to the pump. Therefore, preventing crankshaft failure, with proper operation and maintenance, is critical to the life of your pump.

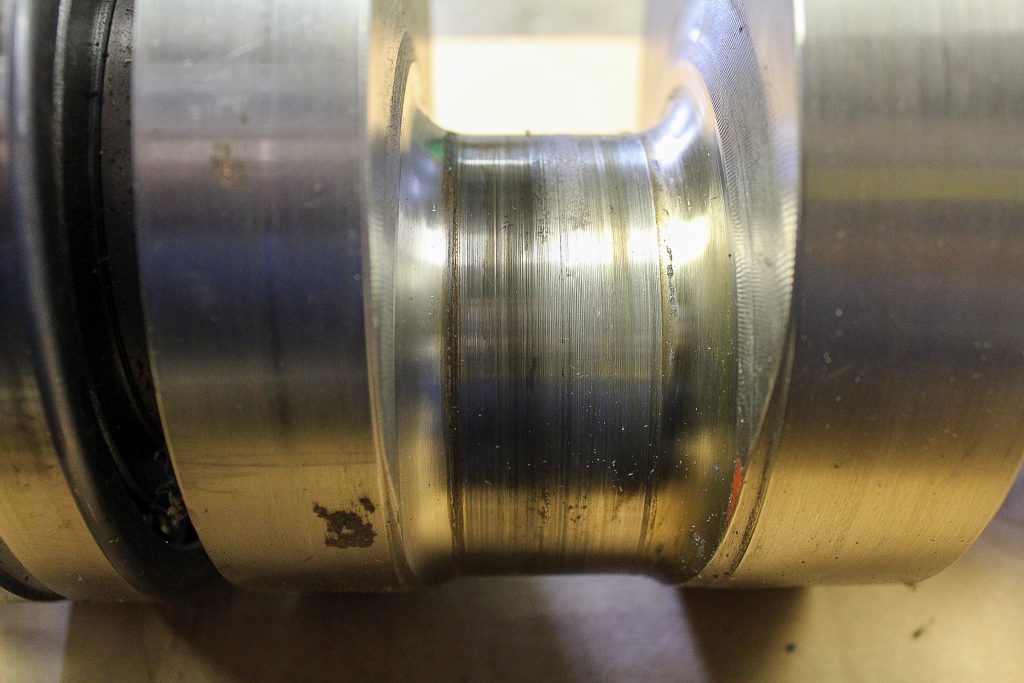

Crankshaft failure can be attributed to the following causes: overload conditions, insufficient lubrication, cavitation, bearing failure to name a few. If these conditions are experienced, the crank shaft should be inspected.

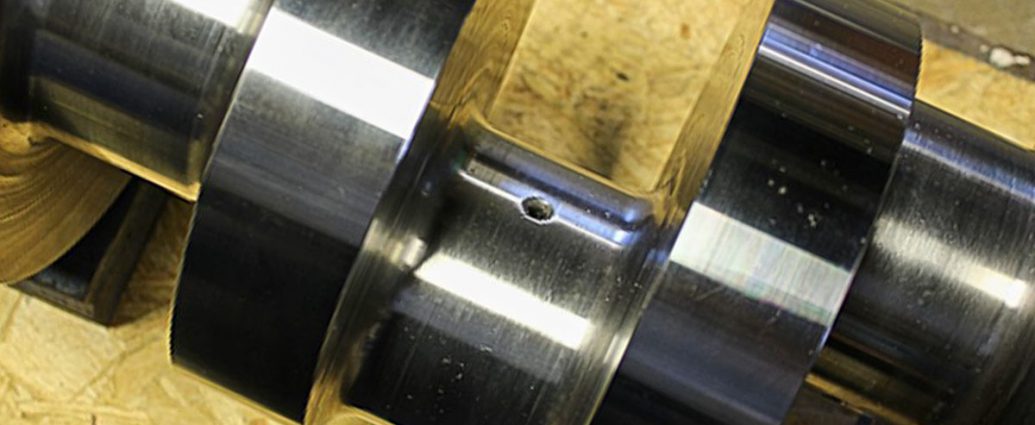

There are proper procedures for crankshaft inspection. First, the crankshaft should be removed from the pump for a full visual inspection. Crankshafts with bad keyways, visible journal wear or worn thrusts surfaces should be discarded. Once qualified for further inspections, there are two standard methods one can use for the evaluation: the die-check and the magna-flux. These methods help to identify microscopic cracks/damage. Once a thorough inspection is completed and passed, the part is ready for reuse. It should be noted, adhering to strict OEM quality standards, pump crankshafts should never be welded or repaired.

It is vital that all testing is completed by a certified, factory-authorized technician. If you have any further inquiries, call Chemac Inc (1-800-217-8677) for assistance and consultation.