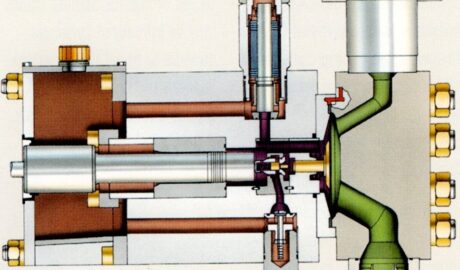

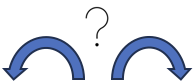

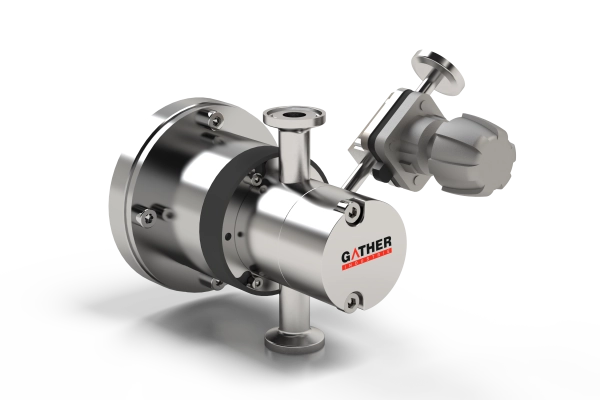

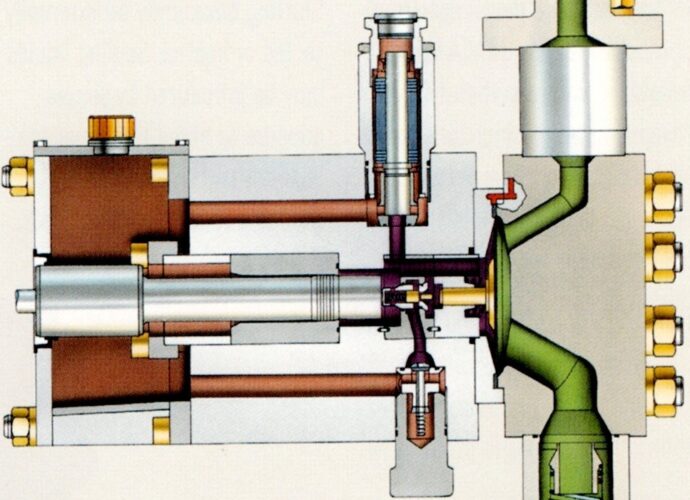

Plunger Pump Design – Exploring Varying Liquid End Designs for Plunger Pumps

January 6, 2026 | Alvin, TX The liquid end of a plunger pump, where the fluid is handled, comes in various designs tailored to specific industrial needs. These designs influence compatibility with different fluids, pressure capabilities, and maintenance requirements. A common type is the packed plunger design, which uses packingRead More →