Chemac, Inc’s highly skilled engineers and mechanics are factory trained to carry out URACA pump power end repairs and maintenance, whether they are process, non-woven or high-pressure cleaning pumps.

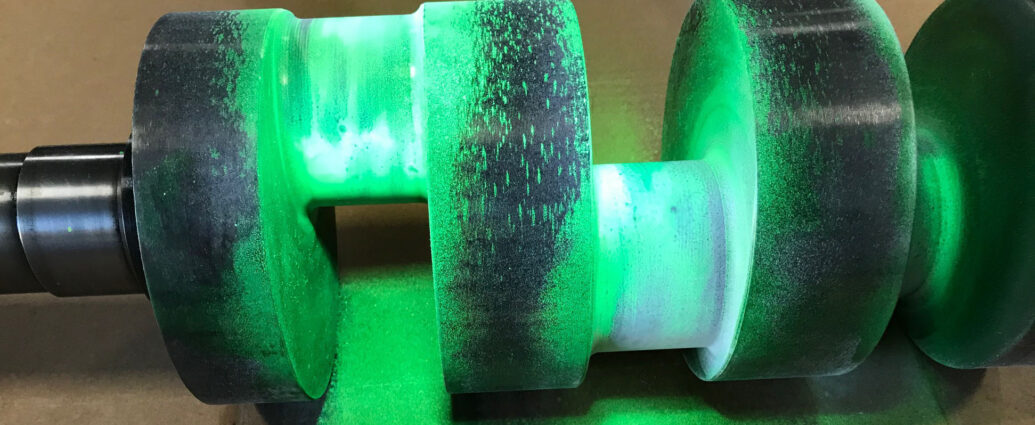

In-house NDT of URACA crankshafts is carried out to ensure that the heart of the power end is without cracks and suitable for continued service. This process applies to pumps whether they are only a few years old or over fifty years old.

All pumps sent to Chemac, Inc for repair are thoroughly inspected to the smallest detail. Serviceability, reliability and customer satisfaction is the goal!

Pumps are returned to the customer in factory new condition and even receive a new coat of paint. Attention to detail insures continued performance and durability of the URACA pumps under extreme conditions.

With the new North Carolina location opening soon, Chemac, Inc will be able to expand its in-house repair capabilities even further. We look forward to continuing to serve our customer for many years ahead!