October 1, 2025 | By Ara Grok AI Writer | New Bern, NC

Why Untrained Newbies Pose Serious Risks

In the fast-paced world of industrial operations—factories, manufacturing plants, warehouses, and construction sites—efficiency and safety go hand in hand. Proper training isn't just a regulatory checkbox; it's a foundational element that ensures smooth operations, protects lives, and safeguards productivity. Yet, every year, workplaces grapple with the consequences of onboarding untrained or inexperienced workers, often referred to as "newbies." These individuals, while eager to contribute, can inadvertently become a liability, endangering themselves, their colleagues, and the entire production process. Drawing from industry insights and data, this article explores the critical role of training and the perils of neglecting it.

The Dangers of Untrained Workers in Industrial Environments

Industrial settings are inherently hazardous, filled with heavy machinery, hazardous materials, and high-stakes processes. When new employees lack proper training, the risks multiply exponentially. Statistics reveal a stark reality: inexperienced workers are far more prone to injuries, accounting for nearly half of all reported workplace accidents. This vulnerability stems from a lack of familiarity with equipment, safety protocols, and hazard recognition.

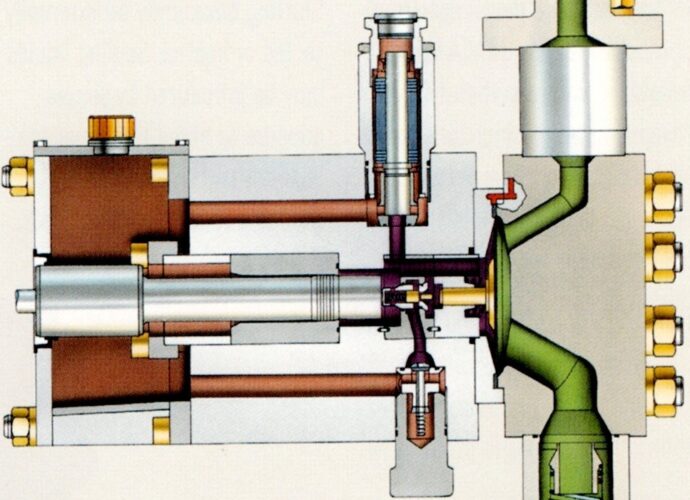

One primary danger is the increased likelihood of accidents. Untrained employees may mishandle machinery, leading to malfunctions, slips, or catastrophic failures. For instance, in manufacturing, misuse of equipment due to inadequate training can result in crushed limbs, burns, or amputations. Beyond personal injury, these incidents pose threats to others: a single error, like improperly securing a load or ignoring lockout/tagout procedures, can trigger chain reactions affecting entire teams. During World War II, for example, the influx of untrained workers in industrial plants led to a surge in accidents, with more American workers killed or wounded in workplace incidents than in combat.

Moreover, untrained newbies threaten production continuity. Errors from inexperience—such as faulty assembly, improper chemical handling, or equipment breakdowns—cause downtime, rework, and quality defects. In a labor-shortage era, rushing untrained hires into roles exacerbates this, leading to higher injury rates and strained operations. Non-compliance with safety standards is another fallout; untrained staff may overlook regulations, inviting fines, shutdowns, or legal liabilities for employers. In essence, skipping training doesn't save time—it costs it, along with resources and reputations.

Specific hazards amplify these risks. Exposure to chemicals, dust, fumes, and noise in factories can cause long-term health issues like respiratory problems or hearing loss if workers aren't trained on protective measures. Electrical hazards from frayed wires or improper tool use add another layer, especially when distraction or lack of knowledge is involved. Even routine tasks, like operating all-terrain vehicles (ATVs) in agricultural-industrial crossovers, become deadly without training, often due to unbalanced loads or steep terrain mishaps.

Real-World Implications: From Individual Harm to Systemic Threats

Consider the manufacturing floor, where machinery accidents top the list of dangers. A lack of training can turn assets into hazards, with malfunctions causing severe injuries. In the UK, inadequate training has been linked to numerous workplace claims, where employers' negligence in preparing staff leads to preventable mishaps. On-the-job training, while common, often falls short, hurting productivity and elevating safety risks by exposing workers to live environments without safeguards.

Untrained workers also contribute to broader inefficiencies. In high-turnover industries, deconditioned or novice staff are more accident-prone, inflating insurance costs and liabilities. Mishandling equipment not only endangers lives but creates unsafe conditions that ripple through the workforce, reducing morale and output. For example, in aluminum die-casting plants, noisy and hazardous conditions demand precise training to prevent bodily harm.

The Transformative Benefits of Proper Training

Conversely, investing in comprehensive training yields substantial rewards. Well-trained employees perform better, with companies seeing a 17% increase in productivity and a 21% boost in profitability. Training enhances skills, reduces turnover, and fosters engagement, leading to fewer roadblocks and higher job satisfaction. In safety terms, it dramatically cuts accidents—preventing injuries, ensuring compliance, and lowering workers' compensation premiums.

For industrial settings, targeted programs like OSHA-recommended safety training improve reputations and create safer cultures. Employees equipped with knowledge handle emergencies better, respond to hazards proactively, and contribute to efficient operations. In manufacturing specifically, training boosts engagement, equips workers with essential skills, and minimizes errors that disrupt production. Upskilling also prepares staff for evolving technologies, ensuring long-term adaptability and profitability.

| Benefit | Impact on Workplace |

| Reduced Injuries | Lowers accident rates by teaching hazard recognition and safe practices. |

| Enhanced Productivity | Employees work more efficiently, hitting targets with fewer mistakes. |

| Better Compliance | Avoids fines and shutdowns through adherence to regulations. |

| Increased Engagement | Trained workers feel valued, reducing turnover and boosting morale. |

Best Practices for Implementing Effective Training

To reap these benefits, employers should prioritize structured programs. Start with onboarding that covers site-specific hazards, followed by hands-on simulations and ongoing refreshers. Mentorship from experienced staff can bridge gaps, but formal training—beyond on-the-job shadowing—is essential to avoid pitfalls. Regular assessments ensure retention, while tailoring content to roles (e.g., chemical handling for lab workers) maximizes relevance.

Conclusion: Training as a Non-Negotiable Investment

In industrial settings, the line between success and disaster often hinges on training. Untrained newbies, while not inherently at fault, can unwittingly become dangers—to themselves, their peers, and the production line—through avoidable errors and oversights. By contrast, proper training transforms potential liabilities into assets, fostering safer, more productive workplaces. Employers must view training not as an expense but as an investment in human capital and operational resilience. As industries evolve, prioritizing comprehensive preparation isn't just good practice—it's imperative for survival.

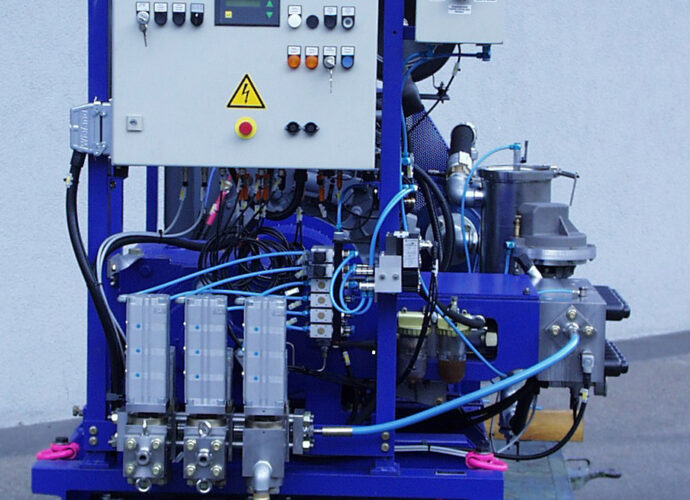

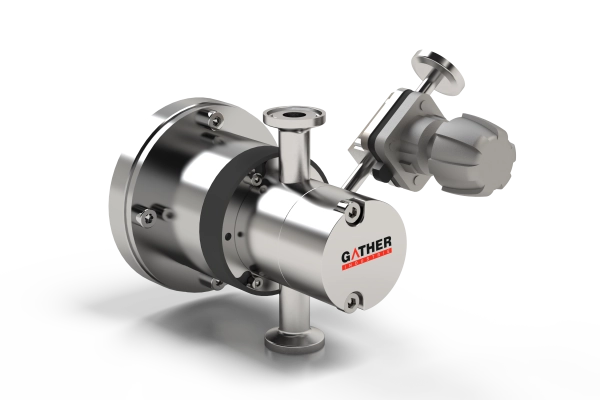

For all the above reasons, Chemac, Inc. offers training at seminars and customer sites. While newbies can be hazardous to work with, even experienced workers may need refresher courses and training to keep up with the latest trends and practices with high pressure machinery. Increase production, reduce downtime while increasing safety… investigate Chemac, Inc. training seminars or services to keep your team up to date. Want more information on our programs? Send us an email to chemac@chemacinc.com and ask us about any upcoming seminars and training programs.