- 9/29/2025 -

By Ara Grok, Staff Writer Teaneck NJ

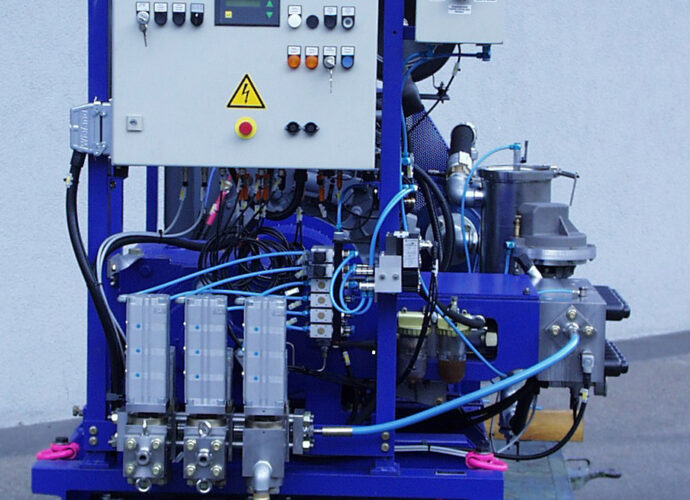

Industrial plunger pumps and valves are critical components in various sectors, including manufacturing, oil and gas, water treatment, and chemical processing. These devices are designed for high-pressure applications, but they are vulnerable to the harsh effects of cold weather. Freezing temperatures can lead to fluid solidification, component cracking, corrosion, and operational failures, resulting in costly downtime and repairs. Understanding the risks and implementing protective measures is essential for maintaining efficiency and longevity. This article explores practical strategies to safeguard these assets during winter conditions.

Understanding the Risks

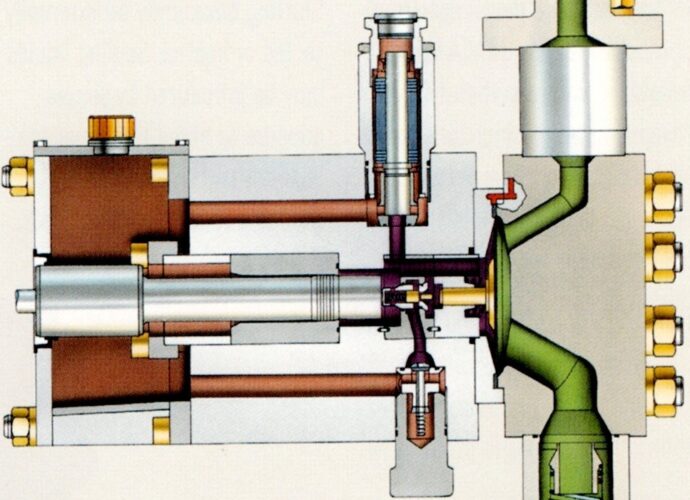

Cold weather poses several threats to plunger pumps and valves. Water or other fluids inside the system can freeze, expanding and potentially cracking pump casings, valves, or seals. In hydraulic systems, low temperatures can thicken fluids, increasing viscosity and causing excessive wear on moving parts. Additionally, moisture condensation can lead to rust and corrosion, while frozen actuators or controls may impair functionality. For plunger pumps specifically, which rely on precise reciprocating motion, ice formation in the intake or discharge lines can halt operations entirely. Valves, often exposed in outdoor setups, face similar issues with breather plugs or seals freezing shut. Proactive protection can mitigate these problems, ensuring reliable performance even in sub-zero environments.

Protective Measures for Plunger Pumps – Suggested for Water & Similar Applications

Plunger pumps, known for their durability in high-pressure scenarios, require targeted interventions to withstand cold snaps. Here are key steps:

- Insulation and Heat Tracing: Wrap the pump body, intake sections, and discharge lines with insulating materials like foam or blankets to retain heat and prevent freezing. Electric heat tracing cables can be installed along pipes to maintain a consistent temperature above freezing point. This is particularly effective for pumps handling water-based fluids.

- Use of Antifreeze Solutions or Pump Protectors: Introduce specialized pump protector fluids that lower the freezing point to as low as -25°F (-29°C). These solutions not only prevent ice formation but also lubricate seals, valves, and seats, inhibiting corrosion and mineral buildup. For winterizing, flush the system with these protectors after draining any residual water.

- Draining and Drying: Before cold weather sets in, thoroughly drain all fluids from the pump to avoid ice expansion damage. This is crucial for diaphragm-style plunger pumps, where undrained water can crack components. Ensure no slush remains in the system, as partial freezing can still cause issues.

- Appropriate Heating Sources: Install space heaters or enclosures around the pump setup to maintain ambient temperatures. For outdoor installations, consider heated pump houses or enclosures that shield against wind and precipitation.

- Battery and Electrical Maintenance: Keep batteries fully charged, as cold reduces their efficiency and can prevent pumps from starting. This is vital for electric or diesel-driven plunger pumps used in remote or temporary setups.

- Design for Cold or Hot Temps – the best is to design stationary systems and trailer mounted units is to advise the pump supplier the anticipated weather conditions where the pump units will be installed or used. The supplier, or OEM, can advise the best options for handling any adverse weather conditions. Systems designed for temperature deviations should also consider maintenance. Buyers should inquire how any temperature related modifications could impact maintenance. It’s always best to provide worst case scenarios for temperature swings to ensure the systems withstand all possible environmental variables.

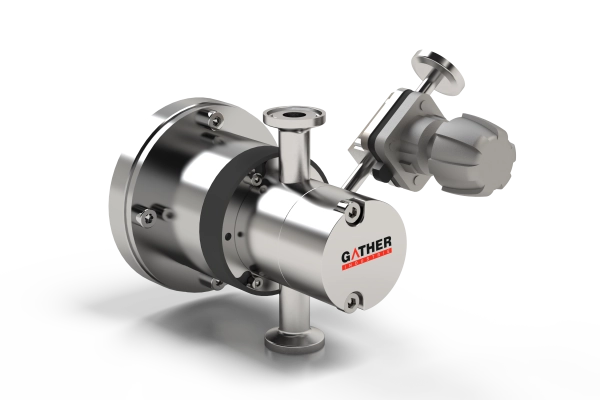

Safeguarding Valves in Cold Conditions

Valves control flow and pressure in industrial systems, and their failure due to cold can disrupt entire operations. Protection strategies include:

- Orientation and Design Adjustments: Position breather plugs on back pressure regulators or control valves facing downward to prevent moisture accumulation and freezing. This simple adjustment can significantly reduce ice-related blockages.

- Fluid and Lubricant Selection: In gas-over-hydraulic actuators commonly paired with valves, switch to high viscosity index (HVI) 15-weight oil for better cold-weather performance. Install pre-filters in wet gas applications to remove contaminants that could exacerbate freezing.

- Insulation Techniques: Similar to pumps, insulate valve bodies and connected piping. Use weatherproof covers or jackets to protect against direct exposure to snow and ice.

- Regular Inspections: Monitor for signs of frost or condensation during cold spells. Apply anti-corrosion coatings or sprays to exposed metal surfaces to ward off rust.

Storage Considerations for Idle Equipment

If pumps and valves are not in use during winter, proper storage is key to preventing damage:

- Surface Protection: Apply a light layer of oil or silicone spray to the pump's exterior to shield against moisture and rust. Store in a dry, temperature-controlled environment if possible.

- Complete Winterization: Follow manufacturer guidelines for flushing and protecting internal components. For plunger pumps, ensure all three winterizing methods—such as antifreeze circulation, air purging, or complete disassembly—are considered based on the model and applications.

- Hydraulic System Prep: For systems with valves, use fluids optimized for low temperatures to avoid thickening and ensure smooth reactivation in spring.

Conclusion

Protecting industrial plunger pumps and valves from cold weather demands a combination of insulation, fluid management, and preventive maintenance. By addressing these vulnerabilities early, operators can avoid unexpected failures and extend equipment life. Always consult equipment manuals and industry experts for model-specific advice, and consider regional climate factors when planning. With these measures in place, your industrial systems can operate reliably through the harshest winters, minimizing risks and maximizing productivity.