January 6, 2026 | Alvin, TX

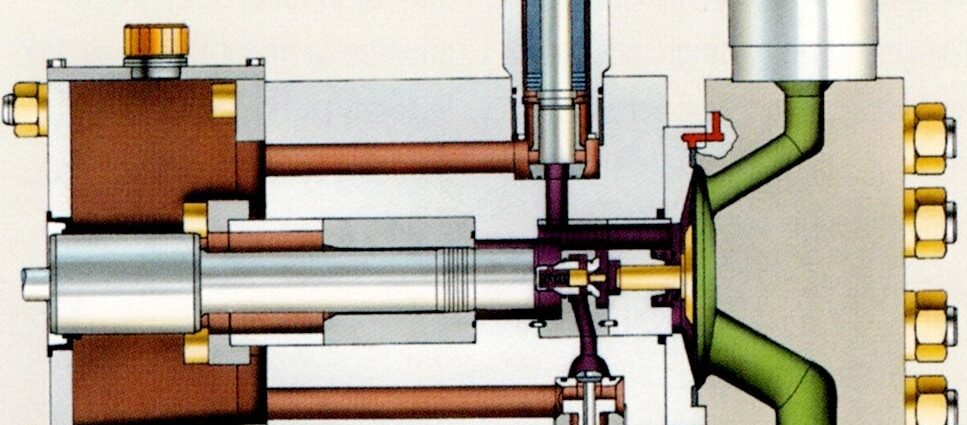

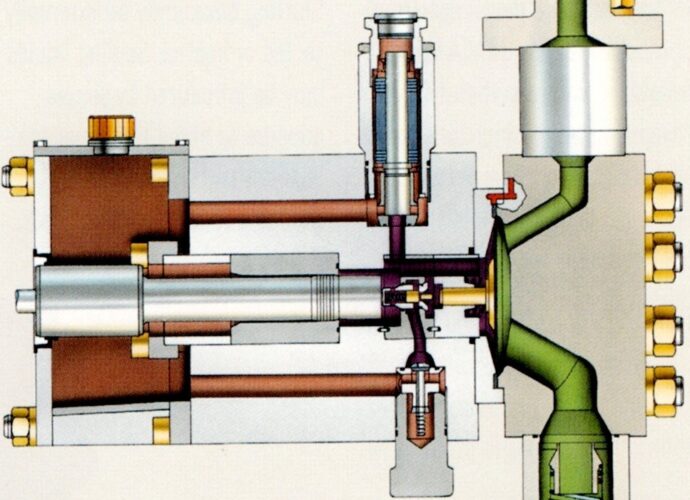

The liquid end of a plunger pump, where the fluid is handled, comes in various designs tailored to specific industrial needs. These designs influence compatibility with different fluids, pressure capabilities, and maintenance requirements. A common type is the packed plunger design, which uses packing rings to seal the plunger. This is suitable for handling “clean”, non-abrasive fluids at moderate pressures, offering ease of maintenance through adjustable packing. Packing designs can handle high pressure up to 40,000 psi or more.

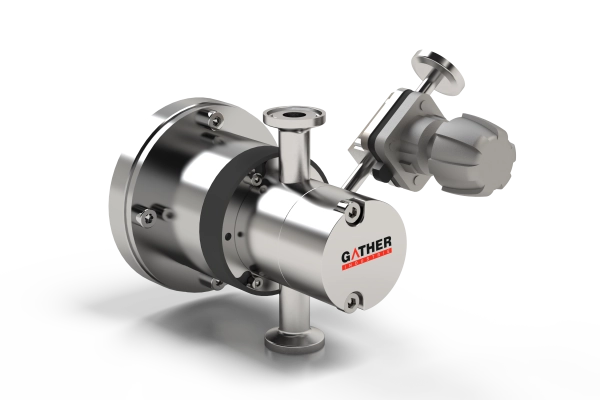

For more aggressive environments, the diaphragm liquid end isolates the plunger from the fluid using a flexible membrane. This design prevents contamination and is ideal for corrosive or hazardous chemicals, as it eliminates direct contact between mechanical parts and the process fluid, enhancing safety and longevity.

High-pressure variants often feature ceramic or hardened alloy plungers in the liquid end to withstand abrasion from slurries in mining or drilling operations. These materials extend service intervals and reduce wear. Selecting the appropriate liquid end design depends on factors like fluid properties, operating pressure, and regulatory demands, ensuring optimal performance and reliability in plunger pump systems.

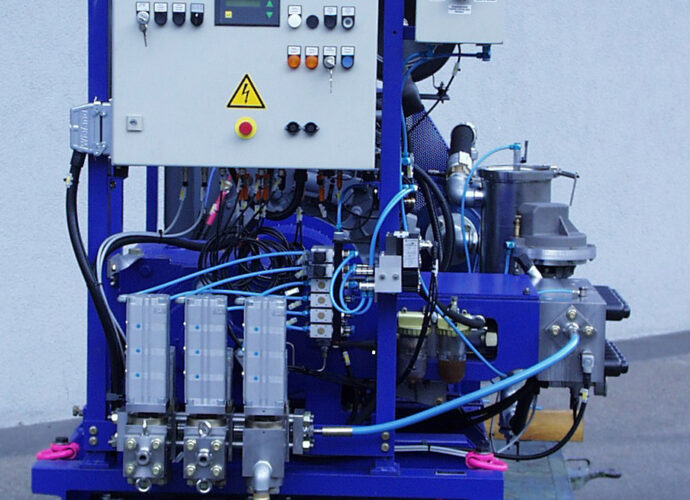

Not sure what material or design suits your application? Reach out to Chemac, Inc. before investing in a design that can potentially upset your process in the future. Finding the right design, material and quality manufacturer is critical to ensure long operating life of your process.