Chemac Inc. offers Hydraulic Intensifier Pumps for the following services:

- Catalyst injection pumps in low-density polyethylene plants Discharge pressures: 1,500 to 4,000 bar (20,000 to 60,000 psi) Capacities: 20 to 140 l/hr (5 to 40 gph)

- Modifier & comonomer injection pumps in low-density polyethylene plants Discharge pressures: 250 to 365 bar (4,000 to 6,000 psi) Capacities: 600 to 3,000 l/hr (160 to 800 gph)

- Testing pumps for autofrettage, rupture tests & pressure tests. These units can be foundation mounted or supplied for trailer mounting which makes them mobile for use anywhere in the plant. Discharge pressures: 4,000 to 14,000 bar (60,000 to 200,000 psi) Capacities: 20 to 100 l/hr (5 to 25 gph)

- Pressurizers for isostatic pressing facilities and for jet cutting units

- Proportional injection pumps for very small volumes

Chemac Inc. has sold a myriad of LDPE, testing, specialized Catalyst injection, and other intensifier units for applications needing ultra-high pressure.

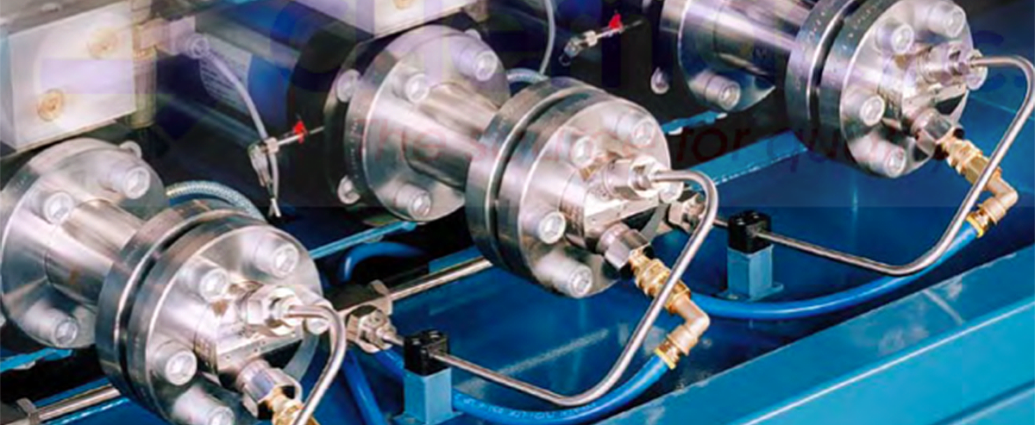

The standard high-pressure pumps with hydraulic drive are plunger pumps with two or four plungers. Basically, they are hydraulic pressure intensifiers, consisting of a hydraulic low-pressure part and high-pressure part. The purpose of separating these two basic parts is to enable the pumps to be assembled by the unitized construction principle.

The low-pressure part is fed by a variable-output axial piston pump which is driven by a constant-speed electric motor. The hydraulic oil from the axial piston pump is alternately directed by a mechano-hydraulic four-way valve, which is hydraulically actuated by the moving plungers, to the two ends of a double-acting hydraulic cylinder whose piston rods are positively coupled to the plungers of the high-pressure part.

Control of the discharge rate of the high-pressure part during standstill and also while the pump is in operation is effected by regulating the axial piston pump throughout, proportionally to the stroke frequency. In addition, the discharge rate may also be varied during standstill by changing the stroke length. The pumps allow extremely accurate flow and pressure.

Service

Chemac Inc. has locations in NJ and Texas for easy access to customers throughout North America. Chemac Inc.’s long standing relationship with sub-suppliers ensures customers with prompt responses and quick delivery of in stock spare parts.

Available Accessories

- HP and LP process piping

- Cooling circuit piping

- Stroke counter with F/I converter

- Air-filter pressure reducing equipment

- Rupture discs

- Flush systems

- Variable frequency drives

- Reservoir heater

- Local/remote conrol cabinet

- Special adapters for all connections

- Discharge pressure gauges

- Spare parts kits

Contact Chemac Inc. for more information on Hydraulic Intensifier Pumps