October 6, 2025 | By Ara Grok AI Writer | New Bern, NC

In the demanding realm of industrial operations, where reliability under extreme pressures can make or break efficiency, Chemac Inc. stands as a beacon of innovation and steadfast support. Founded in 1966 and headquartered in New Bern, NC, Chemac has evolved from a specialized distributor into a comprehensive provider of high-pressure pumps, valves, cleaning systems, and sealing equipment. With stocking facilities in Alvin, Texas—and additional operations in New Bern, North Carolina—this privately held company serves critical sectors like chemicals, petrochemicals, oil and gas, and fertilizers. Over nearly six decades, Chemac's legacy is not just in the machinery it supplies but in the enduring service ethos that ensures industries keep running smoothly, even in the face of global challenges.

Roots in Innovation: A Partnership Forged in 1966

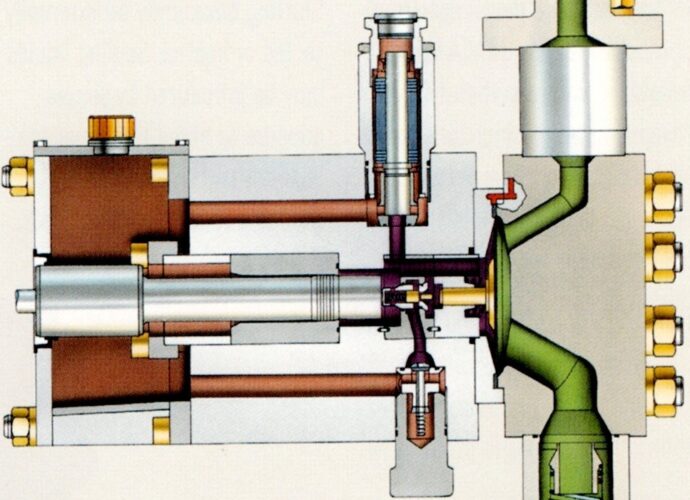

Chemac's story is inextricably linked to its foundational partnership with URACA GmbH & Co. KG, the German plunger pump pioneer established in 1893 by Gustav Magenwirth and Friedrich Krumm in Bad Urach. URACA's origins trace back to the late 19th century, a time of explosive industrial growth marked by Karl Benz's automobile patent, the Wright brothers' early flight experiments, and Rudolf Diesel's engine breakthrough—all innovations that Magenwirth contributed to through his work on piston engines. Though URACA's founders initially aspired to build cars, the company pivoted to high-pressure pump manufacturing, becoming a global leader resilient through world wars and economic upheavals.

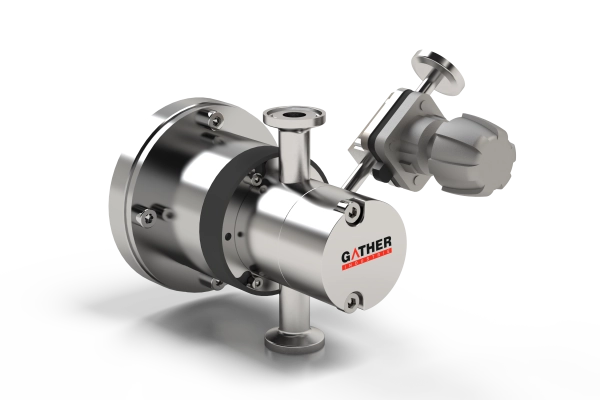

Chemac entered this legacy in 1966 as URACA's exclusive U.S. sales representative and service center, aligning with the German firm's commitment to quality and longevity. This collaboration set the tone for Chemac's growth: from a modest operation focused on industrial machinery distribution to a multifaceted enterprise with ISO-certified factories and Total Quality Standards. By the 1990s and 2000s, Chemac expanded its portfolio through strategic partnerships—Kempchen for sealing equipment in 1995, Gather for magnetic drive pumps in 2000, and Bungartz for centrifugal pumps in 2015—solidifying its role as a one-stop source for high-pressure needs.

Core Offerings: Engineering Reliability Across Three Divisions

At the heart of Chemac's operations are three specialized product divisions, each tailored to tackle the unique pressures of industrial applications:

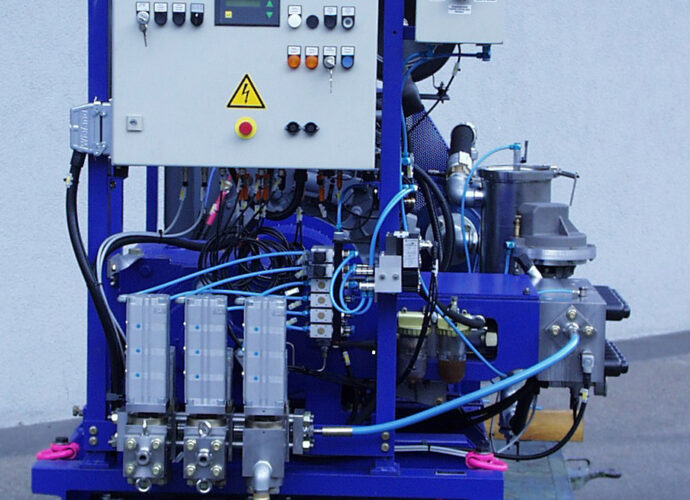

- High Pressure Water Division: Specializing in water-blasting tools, concrete removal systems, confined space cleaners, 2D/3D nozzles, and water jet cutting equipment. These solutions are vital for maintenance in refineries and manufacturing plants, where precision cleaning prevents costly downtime.

- Process Equipment Division: Delivering positive displacement pumps, valves, and piping for chemical, petrochemical, and oil & gas processes. Handling everything from aggressive fluids to high-viscosity media, these systems ensure safe, efficient material transfer under extreme conditions.

- Sealing Equipment Division: Providing static gaskets, packing, compensators, and custom seals for leak-proof performance in high-pressure environments. Kempchen's century-old expertise, integrated since 1995, enhances Chemac's ability to solve sealing challenges in hazardous applications.

Complementing these are Chemac's value-added services through its Service & Support Division: rapid parts availability (24-hour turnaround for in-stock items), on-site repairs, maintenance contracts, operator training, and technical consultations. With same-day shipping and a focus on product advancements—Chemac doesn't just sell equipment; it engineers enduring solutions.

| Division | Key Products/Services | Primary Industries Served |

| High Pressure Water | Water-blasting, 3D cleaning heads & systems, jet cutting etc. | Refineries, Manufacturing, Power Generation |

| Process Equipment | Plunger/magnetic drive/centrifugal pumps, valves, piping etc. | Chemicals, Oil & Gas, Fertilizers |

| Sealing Equipment | Gaskets, packings, compensators etc. | Petrochemicals, High-Pressure Processing |

This integrated approach has made Chemac a trusted partner for projects demanding uptime, from vessel cleaning in chemical plants to pump overhauls or upgrades.

A Legacy of Service: Reliability That Spans Generations

Chemac's true distinction lies in its service legacy—a commitment to longevity that mirrors URACA's 130+ years of support. In an industry where equipment investments are projected for 30-40 year lifespans, Chemac guarantees parts and expertise availability, even through economic disruptions or supply chain strains. This "cradle-to-grave" philosophy has earned the company a reputation for excellence, with clients relying on its responsive team for everything from emergency repairs to predictive maintenance.

Beyond technical prowess, Chemac's contributions extend to workforce development. For over 30 years, it has hosted internships for students from local institutions in North Carolina and Texas, as well as nationwide programs, fostering diverse talent in engineering and manufacturing. Recent initiatives, like the July 2025 "Improving Our Future Through Internships" program, underscore Chemac's role in bridging education and industry, preparing the next generation for high-pressure challenges.

Charting the Future: Sustained Excellence in a Dynamic World

As of September 2025, Chemac Inc. continues to thrive, blending its historical roots with modern demands for sustainability and digital integration. With a global network through partners like URACA—now employing over 330 specialists—Chemac is poised to lead in eco-friendly high-pressure technologies, such as energy-efficient pumps for green chemical processes.

From its 1966 inception to today's multifaceted operations, Chemac Inc. exemplifies how dedicated service can transform industries. In a sector defined by pressure, Chemac delivers not just equipment, but the peace of mind that comes with a legacy built on trust, innovation, and unrelenting support. For industries pushing boundaries, Chemac remains the source for quality that endures.