- 6/23/2025 -

Regular maintenance of pumps is vital for ensuring their longevity and optimal performance. To effectively manage maintenance, use the V.I.N. approach, which stands for Visual, Internal, and Noise.

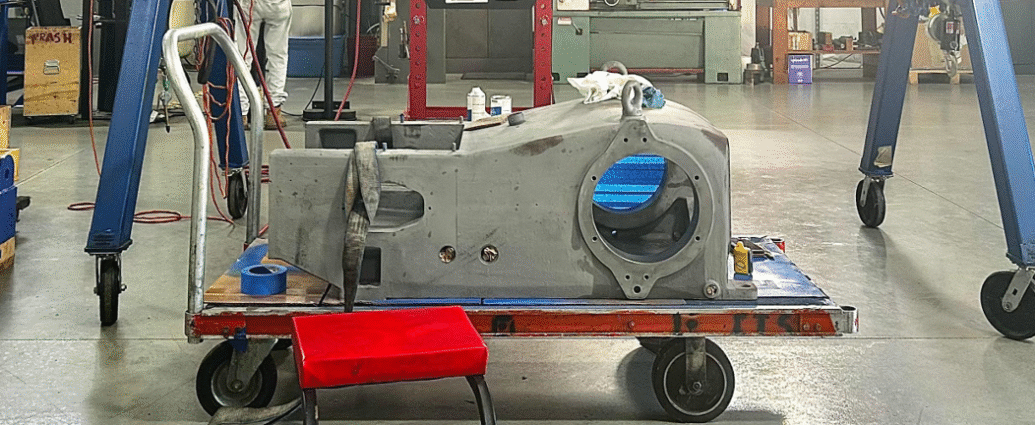

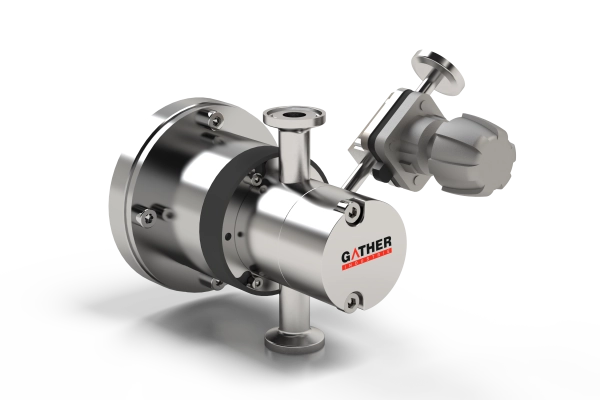

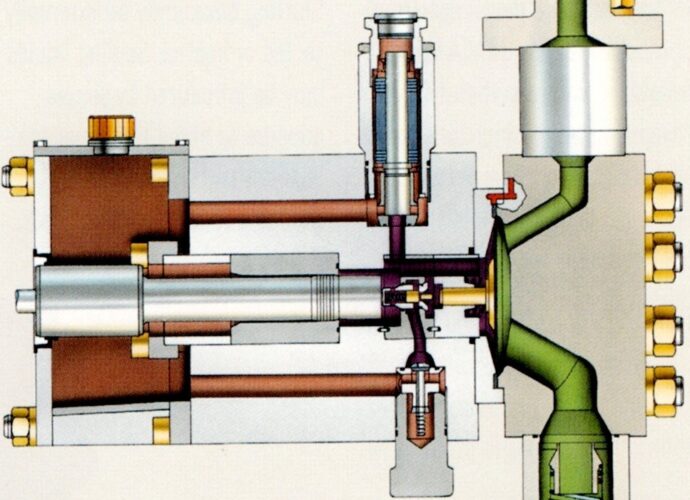

Visual (Inspection): Start with a thorough visual check. Look for leaks at connections and seals, dirt or debris in vents and windings, and signs of wear or corrosion. Ensure that the pump and motor are properly aligned, as misalignment can lead to increased wear.

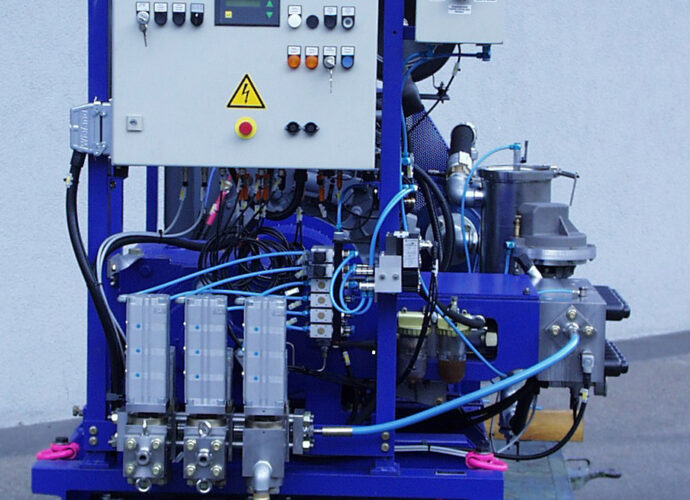

Internal (Monitoring): Monitor the flow rate and discharge to confirm the pump is operating within specifications. Check temperature readings, as elevated temperatures may indicate overworking or friction. Regularly inspect the control panel and wiring for any signs of damage.

Noise (Evaluation): Listen for any unusual sounds, such as rattling, knocking, grinding, or humming. These noises may suggest cavitation or deeper issues with the pump.

If you notice any of these symptoms, it’s crucial to act quickly. Refer to our Instruction Book for troubleshooting or contact our support team for assistance. Taking proactive steps in pump maintenance will help ensure efficient operation and extend equipment lifespan.