February 9, 2026 | New Bern , NC

In the demanding world of industrial fluid handling, where precision, durability, and efficiency can make or break operations, URACA process pumps stand out as a beacon of engineering excellence. With over 130 years of innovation since its founding in 1893, URACA GmbH & Co. KG has pioneered high-pressure technology, delivering pumps that operate at pressures up to 3,000 bar (43,500 psi) and power ratings up to 2,600 kW (3,500 HP). These German-made marvels are not just equipment—they are strategic investments that promise long-term cost savings, enhanced productivity, and unparalleled process reliability. For industries like chemical processing, petrochemicals, oil and gas, and manufacturing, choosing URACA means investing in a future-proof solution that minimizes downtime and maximizes output.

Robust Power End Designs: Built for Endurance and Efficiency

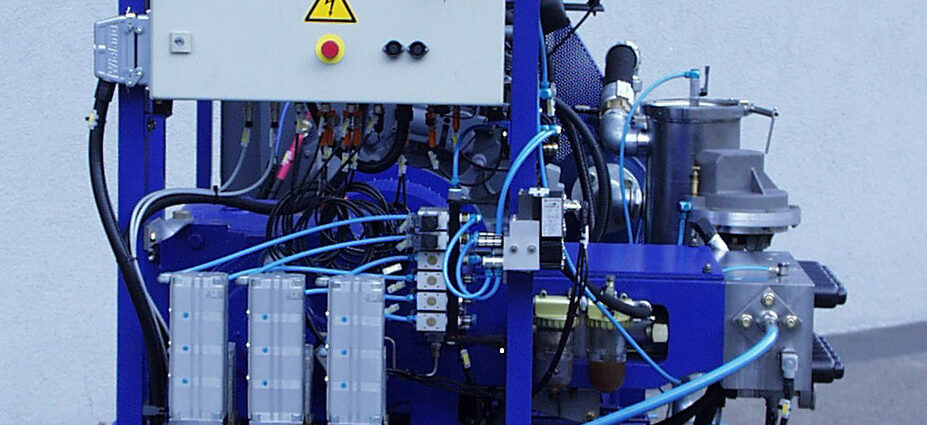

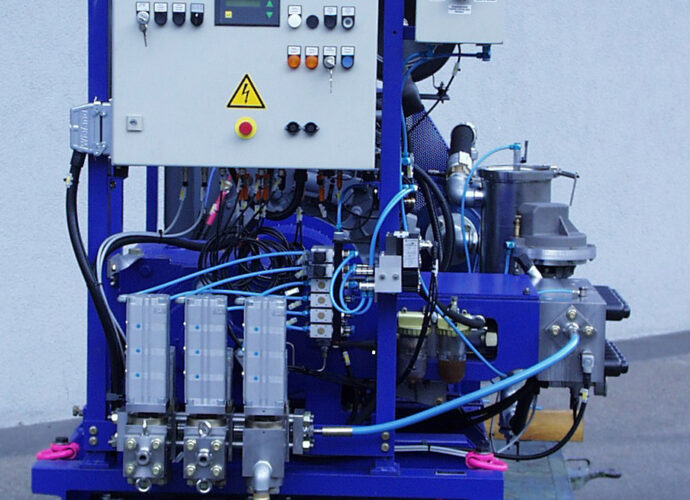

At the heart of URACA's superiority lies its power end designs, engineered for continuous, heavy-duty operation around the clock—for decades. These standardized power ends feature a compact architecture with an exceptional power-to-weight ratio, allowing for seamless integration into space-constrained environments without sacrificing performance. Models like the P-Series (including P3-80, P5-80, and P7-80) incorporate multi-plunger configurations—three, five, or seven plungers—that minimize pressure pulsations, ensuring smooth, consistent flow even under extreme loads.

What sets URACA apart is the focus on low operating costs through innovative features like high-efficiency drives and minimal maintenance requirements. The power ends are designed to handle motor ratings from 20 kW up to multi-megawatt levels, making them versatile for everything from intermittent cleaning to non-stop industrial processes. This durability translates to real-world savings: fewer repairs, extended service intervals, and energy optimization that can reduce operational expenses by significant margins. Imagine a pump that runs flawlessly for years, turning what could be a recurring cost center into a reliable asset— that's the URACA power end advantage.

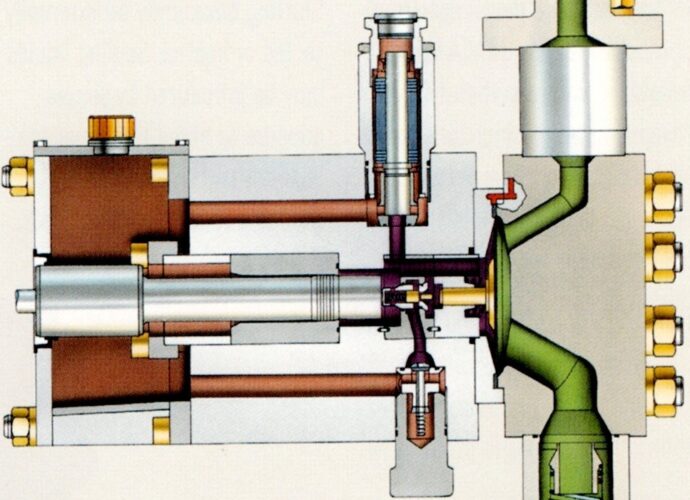

Versatile Liquid End Designs: Customized for Challenging Fluids

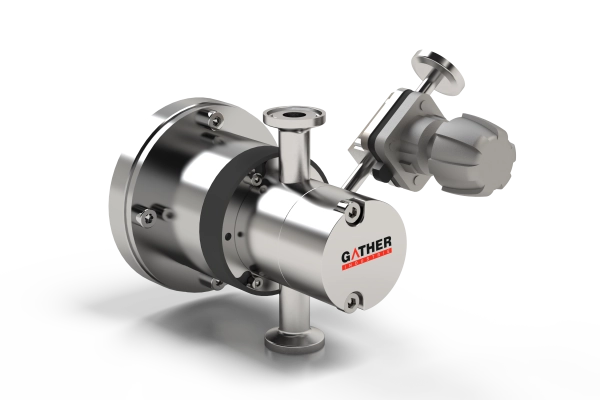

URACA's liquid ends are where customization meets cutting-edge materials science, making these pumps ideal for handling a wide spectrum of media—from thin liquids to pasty, abrasive, aggressive, hot, or toxic substances. Unlike off-the-shelf solutions, URACA liquid ends are tailor-made, with standardized components like valve blocks and stuffing boxes that reduce part variety while allowing for bespoke adaptations. Materials range from carbon and chromium steels to advanced alloys such as duplex stainless steel, aluminum bronze, Hastelloy, tantalum, titanium, or Inconel, ensuring compatibility with corrosive or hazardous fluids.

Innovations like the P3-19 triplex plunger pump exemplify this: smaller, lighter, and stronger than predecessors. Uraca offers flow rates up to 1,450 USGPM and enhanced power density for broader applications. For sensitive environments, process diaphragm pumps provide hermetic sealing to prevent emissions, ideal for toxic or environmentally critical operations. These designs not only enhance safety—complying with stringent regulations—but also boost efficiency by minimizing leaks and contamination risks. In sectors like descaling, deburring, or high-pressure injection, URACA's liquid ends deliver precise performance, turning complex challenges into streamlined processes.

The Investment Edge: Long-Term Value and ROI

What makes URACA process pumps the best investment? It's the synergy of reliability, efficiency, and innovation that yields tangible returns. These pumps are built for 24/7 operation with minimal downtime, backed by over 130 years of know-how and a global network of service centers. Low operating costs stem from energy-efficient designs and reduced maintenance, while high-quality construction ensures longevity that outlasts competitors. Customers report savings in billions through prevented leaks and optimized processes, as URACA units facilitate maximum efficiency and process reliability.

In an era of rising energy prices and sustainability demands, URACA's eco-friendly features—like water conservation in cleaning systems and emission reductions—add environmental value, potentially qualifying for green incentives. Tailor-made solutions mean you're not just buying a pump; you're acquiring a partner in progress, with customizable units that evolve with your needs. Whether for hydrostatic testing, sewer cleaning, or continuous casting descaling, URACA pumps deliver a superior ROI by enhancing safety, cutting costs, and driving productivity.

Investing in URACA isn't about short-term gains—it's about securing a competitive edge for the long haul. With a legacy of superior quality and a commitment to pushing the boundaries of high-pressure technology, these pumps inspire confidence. Don't settle for average; elevate your operations with URACA and watch your investment pump out returns for generations to come. The up front cost may be higher than low cost options, but the ROI over the long run will ensure your process remains operational and profitable.