January 5, 2026 | New Bern, NC

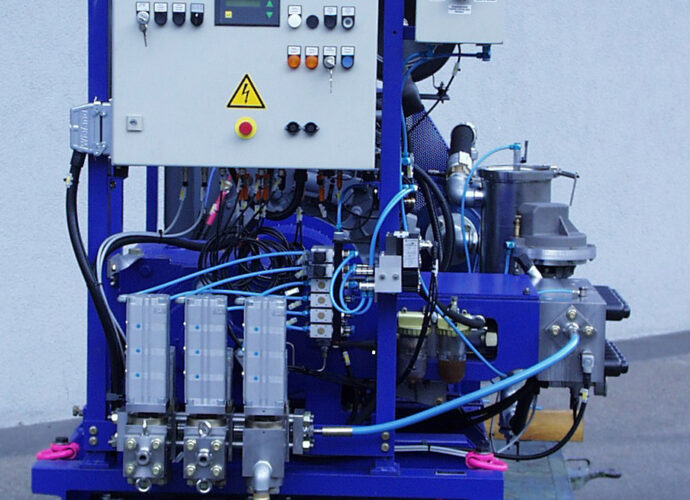

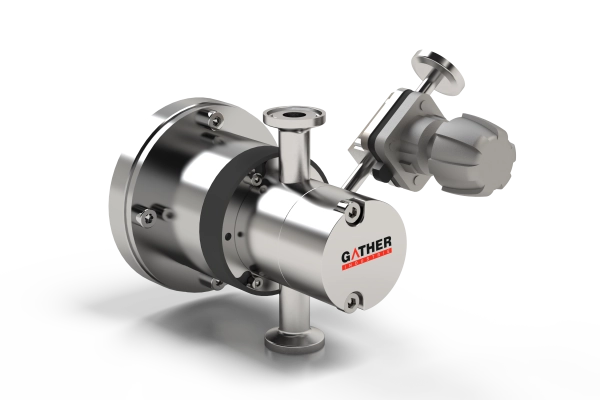

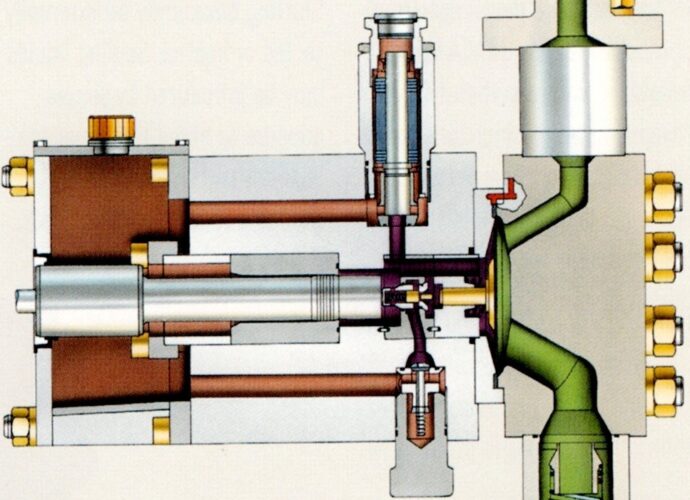

Effective maintenance of high-pressure pumps is essential to prevent breakdowns and extend service life in industrial environments. Regular inspections form the foundation, focusing on seals, valves, and plungers for signs of wear. Lubrication schedules should be adhered to, using appropriate fluids to reduce friction and heat buildup, which can lead to premature failure.

Monitoring pressure and flow rates helps detect anomalies early, such as cavitation caused by air ingress or blockages. Implementing vibration analysis tools can identify imbalances or misalignments before they escalate. For pumps handling abrasive media, routine flushing with clean fluids prevents buildup and erosion.

Scheduled part replacements, based on operational hours, ensure reliability. Training operators on proper startup and shutdown procedures minimizes stress on components. In corrosive settings, selecting compatible materials during initial setup aids long-term maintenance ease. By adopting proactive strategies, industries can achieve minimal downtime, cost savings, and enhanced safety with high pressure pumps.

In order to ensure the lifetime efficiency of your equipment, contact Chemac, Inc. for a service review. Chemac, Inc also offers training and site support as well as repairs off site. Chemac, Inc. is your source for quality.