January 2, 2026 | New Bern, NC

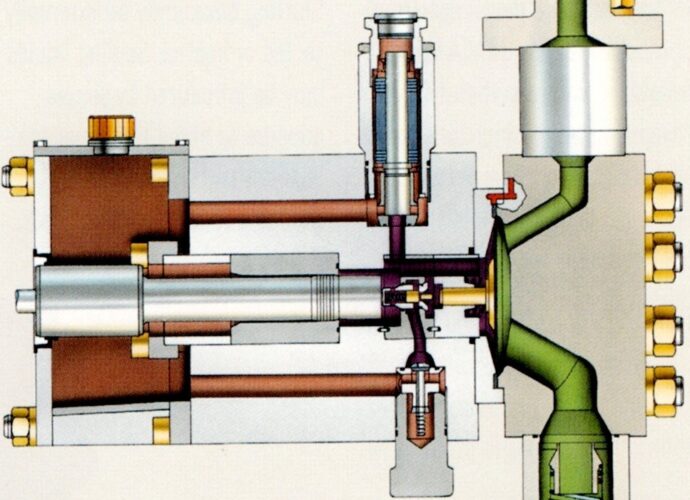

Reciprocating plunger pumps are a cornerstone in many industrial settings due to their robust design and efficient performance under demanding conditions. These pumps operate by using a plunger that moves back and forth within a cylinder, creating high pressure to move fluids. One of the primary benefits is their ability to generate extremely high pressures, often exceeding 1,000 psi, making them ideal for applications requiring forceful fluid delivery, such as in oil and gas extraction or chemical processing.

Efficiency is another key advantage. Reciprocating plunger pumps can handle a wide range of viscosities and are particularly effective with abrasive or shear-sensitive fluids. Their positive displacement mechanism ensures a consistent flow rate, regardless of pressure variations, which enhances process reliability. This consistency reduces downtime and improves overall productivity in manufacturing lines.

Maintenance is relatively straightforward compared to other pump types. The modular design allows for easy replacement of wear parts like seals and valves, extending the pump's lifespan and reducing operational costs. In environments where precision is crucial, these pumps offer adjustable stroke lengths, enabling fine-tuning of output volumes.

Environmentally, they contribute to sustainability by minimizing fluid waste through precise delivery. In water jet cutting or high-pressure cleaning, they optimize resource use, leading to lower energy consumption. Overall, the benefits of reciprocating plunger pumps lie in their durability, efficiency, and adaptability, making them indispensable for industries aiming for high-performance fluid handling.

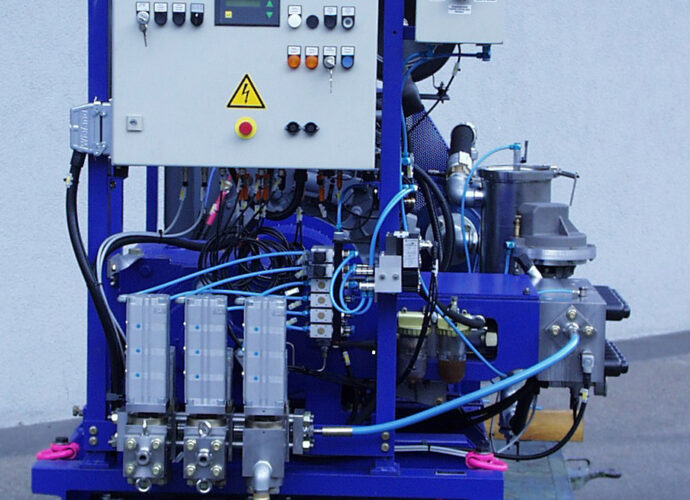

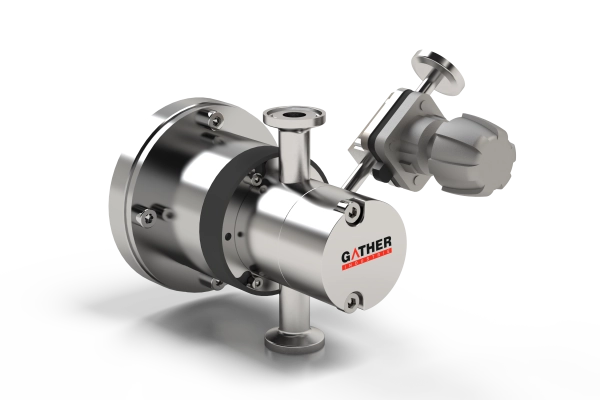

Applicable products offered by Chemac, Inc. – Uraca high pressure pumps.