October 8, 2025 | By Ara Grok AI Writer | New Bern, NC

In the high-stakes world of heavy industry, where precision, durability, and efficiency are non-negotiable, lubrication systems play a pivotal role in ensuring machinery operates smoothly under extreme conditions. Among the most advanced solutions are Morgoil® systems, renowned for their oil film bearing technology. These systems, often deployed in rolling mills and large-scale manufacturing, rely on robust high-pressure pumps to maintain a consistent oil film that prevents wear and friction. Enter URACA GmbH & Co. KG, a German engineering powerhouse that has been at the forefront of this technology since delivering its first Morgoil® pump back in 1968. Today, URACA's specialized pumps continue to drive Morgoil® systems, combining decades of innovation with cutting-edge reliability. This article explores how these two technologies intertwine to transform industrial operations.

The Essence of Morgoil Systems

Morgoil® bearings, developed by Primetals Technologies (formerly Morgan Construction Company), represent a cornerstone of modern hydrostatic lubrication. Unlike traditional hydrodynamic bearings, which depend on shaft rotation to generate an oil film, Morgoil® systems use external high-pressure pumps to create and sustain this film proactively—even before the machine starts moving. This "hydrostatic" approach fills oil pockets in slide bearings with a constant, high-pressure flow, ensuring zero metal-to-metal contact and minimizing friction.

At the heart of a Morgoil® system is an active lubricant circuit designed for demanding environments. It handles pure mineral oils with viscosities up to 1,000 cSt, often filtered to ISO VG 680 standards, to support loads in massive equipment like rolling mill stands. The result? Bearings that exhibit exceptional concentricity, low energy loss, and extended service life—critical for industries where downtime can cost millions.

Morgoil® systems are not just about lubrication; they're engineered for integration. Tailored lubrication setups, including reservoirs, filters, and control valves, ensure seamless performance in continuous operations. Primetals emphasizes precision design, with systems optimized for peak performance in hot and cold rolling applications.

URACA Pumps: The Power Behind the Precision

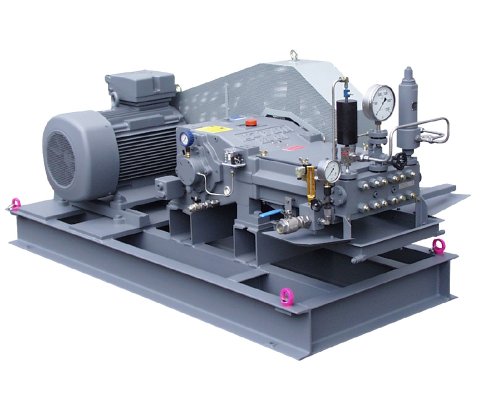

Founded in 1893 in Bad Urach, Germany, URACA has evolved into a global leader in high-pressure pump technology, employing over 330 specialists who craft solutions for the toughest industrial challenges. Their plunger pumps, built to API 674 standards, excel in handling thin to pasty fluids under pressures up to 1,500 bar and flow rates reaching 40 liters per minute. For Morgoil® applications, URACA's triplex plunger designs stand out, offering robust construction with features like belt drives, safety valves, and double filtration to safeguard against contaminants.

What sets URACA pumps apart is their adaptability. They manage aggressive, abrasive, hot, or toxic media while requiring minimal maintenance—ideal for 24/7 operations in oil and gas, or even CO2 extraction processes that parallel Morgoil's® demands. Recent advancements, such as remote monitoring via URACA Remote Control, allow operators to track utilization and maintenance from anywhere, further enhancing system uptime.

Seamless Integration: URACA Pumps in Morgoil Systems

The synergy between Morgoil® and URACA is evident in specialized pump units like the KD-716, explicitly engineered for Morgoil® lubrication. This triplex plunger pump features a compact design with the unit mounted directly over the motor, complete with a V-belt drive and electric motor for easy installation. Key specs include:

| Specification | Details |

| Plunger Diameter/Stroke | 14 mm / 70 mm (3 plungers) |

| Capacity | 10 l/min @ 700 bar; 8 l/min @ 1380 bar |

| Max Pressure | 1,500 bar (safety valve) |

| Pump Speed | 375 rpm |

| Power Requirement | 26 kW @ 1380 bar; 30 kW motor |

| Viscosity Handled | Up to 1,000 cSt (ISO VG 680) |

| Weight | 1,200 kg |

The KD-716 circulates filtered mineral oil at inlet temperatures around 40°C, with connections optimized for suction, discharge, and return flows. Similarly, the KD719 unit adds a belt drive, safety/check valves, and dual filters for enhanced reliability in hydrostatic setups. The KD724 variant incorporates a direct drive electric motor for even greater automation.

In a typical Morgoil® setup, URACA pumps pressurize the oil circuit to form a stable film, reducing wear during startup and shutdown—phases where traditional systems falter. This integration has been refined over 50+ years, with URACA serving over 800 global customers in tailored configurations.

Benefits and Real-World Impact

Pairing Morgoil® with URACA pumps yields transformative advantages:

- Reduced Friction and Wear: Hydrostatic oil films cut energy losses and extend bearing life by decades.

- High Load Capacity: Supports massive machinery with precision, vital for rolling mills processing steel at high speeds.

- Maintenance Efficiency: Low-maintenance designs and remote diagnostics minimize downtime, with systems rated for 20-25 years in harsh environments.

- Water Contamination Resistance: Advanced oils and filtration maintain demulsibility, preventing issues in humid steel mill conditions.

These benefits shine in applications like hot/cold rolling mills, where Morgoil®-URACA combos ensure flawless strip quality and throughput. Beyond metals, they're deployed in power plant turbines and generators for reliable, low-friction operation.

Looking Ahead: A Legacy of Innovation

From the inaugural 1968 Morgoil® pump to today's smart, high-pressure units, URACA's long history of supplying Morgoil® pumps exemplifies engineering excellence. As industries push toward sustainability and automation, these systems will evolve—perhaps incorporating AI-driven predictive maintenance or eco-friendly lubricants. For manufacturers seeking unbreakable reliability, Morgoil® Systems powered by URACA remains the gold standard, proving that in the world of industrial lubrication, pressure truly makes all the difference.